Upgrading a Used

Taurus PT111 G2

by Roy

Seifert

Click here to purchase a zip file with this and

all Kitchen Table Gunsmith Articles.

Disclaimer: This

article is for entertainment only and is not to be used in lieu of a

qualified gunsmith. Please

defer all firearms work to a qualified gunsmith.

Any loads mentioned in this article are my loads for my

guns and have been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of these loads,

or use or misuse of this article.

Please note that I am not a

professional gunsmith, just a shooting enthusiast and hobbyist, as well

as a tinkerer. This

article explains work that I performed to my guns without the

assistance of a qualified gunsmith.

Some procedures described in this

article require special tools and cannot/should not be performed

without them.

Warning: Disassembling

and tinkering with your firearm may void the warranty.

I claim no responsibility for use

or misuse of this article. Again,

this article is for entertainment purposes only!

Tools

and firearms are the trademark/service mark or registered trademark of

their respective manufacturers. Click on any

blue text to go to a

product/seller web site.

Introduction

I have two 9mm semi-autos in my collection; a Beretta 92FS and a 1911 double

stack that I built from parts, but both are too large for every day carry.

I wanted a smaller 9mm pistol for everyday carry.

When I get an idea to purchase another gun, I like to go to

Gunbroker.com to look for a lightly used

model on which no one else is bidding.

In my experience the gun usually has some cosmetic flaws, which for some

reason people donít want to buy, but functions perfectly.

And, it usually doesnít have an extensive number of rounds fired through

it so itís not worn out. My

exception was a Phoenix Arms HP22 I purchased with a broken sear which I was

able to replace to get the pistol functioning again (refer to my article

Repairing a Phoenix Arms HP22).

Gunbroker.com Purchase

Iíve always been impressed with the Taurus Millennium series of pistols ever

since my neighbor showed me the model he purchased.

I already own a Taurus PT 24/7 Pro C DS in .45 Auto, and at one time I

had one in .40 S&W, so I started looking for a similar model in 9mm.

I

found a 9mm PT111 G2 model on Gunbroker.com

for a very reasonable price. It had

some holster wear and scratches on the slide, but otherwise looked ok.

No one wanted to purchase this pistol because of its looks, and the

seller took a credit card with no credit card fee!

One of

the major differences between the PT111 and PT111 G2 (generation 2) is the

takedown method. The generation 1

model used a takedown lever similar to my PT 24/7 that had to be rotated and

pulled out to remove the slide assembly.

The generation 2 model uses a button that needs to be pushed down on both

sides to remove the slide assembly.

I like the sliding button method better.

Refinishing the Gun

One of

the Taurus models that appealed to me was the

GX4 but I decided I didnít want the ďmicro-9Ē configuration.

However, I really liked the tan color.

There are a number of popular firearm finishes available to the hobby

gunsmith.

KG Guncoat 2400, Duracoat,

Brownellís Aluma-Hyde, Cerakote,

hydrographics,

powder coating, and

paint. KG Guncoat is a one-part,

bake-on finish. I have a toaster

oven in my shop I can use to bake the finished parts.

Duracoat is a two-part epoxy finish that does not require baking, but the

two parts must be properly measured and mixed.

I have used Duracoat in the past and like the results.

Cerakote has a number of finishes; some are two-part and some require

baking, but can be difficult to use.

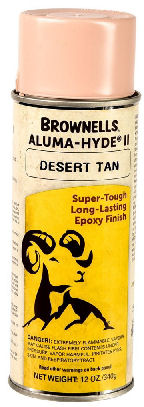

Brownellís Aluma-Hyde is an epoxy-based finish that comes in a spray can.

It can be applied with minimal preparation work.

As for

paint, Iíve painted two rifles with a camouflage pattern (refer to my articles

Building a Backpacker

ďScoutĒ Rifle and

Improving a Chinese Polytech M14S).

After painting I sprayed a matt clear coat on the rifles to prevent wear.

Paint is thick and not the most durable finish, but it is very easy to

repair. Rust-Oleum makes a 6-can

camouflage kit that is very affordable and is available from

Amazon. I have used this before

with excellent results.

Hydro-dipping is the process of dipping the gun into a liquid hydrographic

pattern so it adheres to the part. I

hydro-dipped a shotgun for my nephew (refer to my article

DIY Camouflage for a

Shotgun), Once the part is

dipped, rinsed and dried it is coated with a matt clear coat to protect the

finish. The different patterns are

fantastic, but I donít have any experience with the durability.

Some hydrographic films require two coats of paint; a self-etching primer

then a base coat color, which can be too thick.

Powder

coating applies a colored powder to the part which adheres by static

electricity. The part is then heated

so the powder melts to the surface.

This is a very durable finish, but is very thick; it can affect mating

tolerances of parts. Reloaders are

now powder coating cast bullets to get cleaner, higher velocities with no

leading.

I

decided to use Brownell-s Aluma-Hyde II Desert Tan which looked similar to the

Taurus FDE. I had a can left over

from another project. When I tested

the old can the paint came out in splotches so I purchased a new can.

Preparing the Slide and Frame

I

completely stripped the slide and frame to prepare for painting.

The frame has three parts that are easy to lose; the slide catch spring

in the central support, and the safety detent ball and spring in the mechanism

support. I placed all loose parts in

a plastic tub so they wouldnít get lost.

I

purchased a set of

Mesh Might scuff pads from Amazon.

I used a green, 240-mesh pad to rough-up the slide.

I rubbed until the bare metal just started to appear.

I masked the areas I didnít want to paint and inserted a 1/2-inch dowel

in the barrel opening to hold the slide.

I thoroughly cleaned the slide with isopropyl alcohol.

I sprayed a single coat of the Aluma-Hyde onto the slide and used my heat

gun to dry it.

I

placed the slide in my toaster oven and baked it at 200o for

3.5-hours as recommended on the Aluma-Hyde II can.

Until the slide was baked, I wore nitrile gloves to handle it.

I didnít want to get any skin oils on the cleaned or painted slide.

After

I disassembled the frame, I masked the interior so it wouldnít get coated.

I also masked the serial number on the bottom of the frame.

It is illegal to modify the serial number in any way.

I again cleaned the exterior thoroughly with isopropyl alcohol and

handled it only with nitrile gloves on my hands.

I painted the frame with one coat of the Aluma-Hyde II and allowed it to

cure for one day.

I did

some extensive research on whether I could bake the polymer frame which provided

me with mixed results. Some say do

it, some say not to, some say bake at a lower temperature.

My research also said that most polymer frames are made from Nylon 6/6

which has glass fibers added for strength.

I Googled the melting point of plastic and found the chart shown in

Appendix A at the end if this article.

It shows the melting point of Nylon 6/6 as over 500o

Fahrenheit so I didnít worry about baking it.

I put the frame in my toaster oven set to 100o for 2.5 hours

and it came out perfectly.

I

completely reassembled the slide and frame.

As you can see from the above photo, I am very pleased with the results.

I didnít paint the bottom of the magazine because I didnít want to wait

for the paint to cure.

Modifying the Factory Trigger

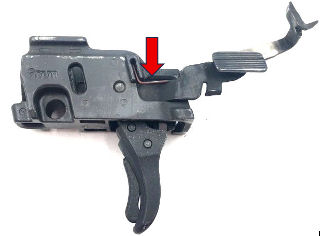

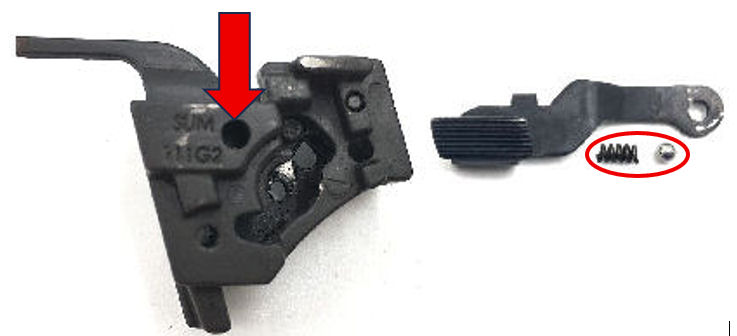

I

decided to try to modify the factory trigger into a short stroke trigger.

I roughened the undercut in the front of the factory trigger and drilled

two 1/16 holes on each side to help hold epoxy.

I placed two brass shims on either side of the trigger coated with paste

wax to act as a dam. I mixed some

JB-Weld and applied it to the front of the trigger building it up.

The brass shims prevented the epoxy from running out.

Once

the epoxy cured, I filed it down until the trigger would function to my liking.

You can see the epoxy in the above photo.

Because the trigger is now so far back the trigger safety no longer

engages and I donít have second strike capability.

However, the amount of trigger take-up before hitting resistance is now

only 1/8 inch which makes the initial and backup shots quick without that long

take up for the first shot. Because

the trigger safety is no longer working, I decided to remove it and save it in

my PT111 spare parts bin. I may

build up the front of the trigger with epoxy then shape it to give me a bit more

thickness.

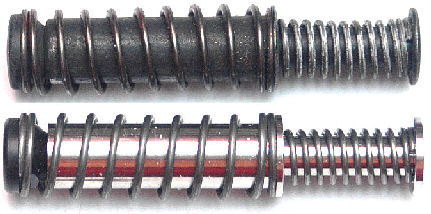

Replacing the Recoil Spring Assembly

I

purchased a

stainless-steel recoil assembly from

Lakeline LLC. This is a drop-in

part that replaces the factory recoil assembly.

I removed the slide from the frame, removed the factory recoil spring

assembly, and replaced it with the stainless-steel version.

I added a few drops of oil to each spring before installing into the

slide.

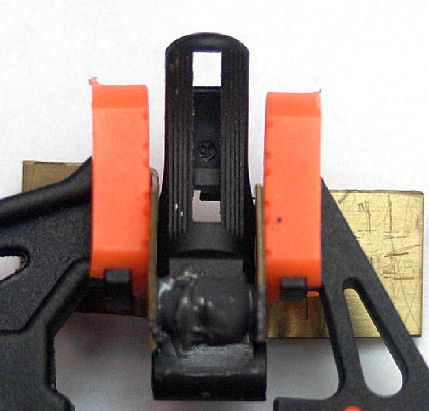

Replacing the Plastic Firing Pin Sleeve

I also

purchased a

stainless-steel firing pin sleeve from Lakeline LLC (they call it a striker

guide). This replaces the factory

plastic sleeve. Bear Family

Homesteading has a

YouTube video

on how to remove and replace the firing pin/striker.

I installed the new sleeve as follows:

1.

Ensure

the gun is clear and the magazine is removed.

2.

Remove

the slide from the frame.

3.

Turn

the slide upside down and press the orange plastic sleeve towards the front of

slide.

4.

Remove

the slide cap.

5.

Carefully release spring tension from the striker and sleeve.

6.

Remove

the striker and sleeve.

7.

Place

the striker assembly on a hard surface with the sleeve down.

8.

Press

down on the firing pin spring and remove the two plastic retaining clips from

the firing pin.

9.

Carefully remove spring tension and remove the spring and sleeve.

10.

Install the new sleeve.

11.

Place

the assembly with the sleeve down on a 1/8 piece of wood or a wooden dowel.

This is to prevent the striker from falling down inside the sleeve.

12.

Press

down on the firing pin spring to expose the collar at the top of the firing pin

and install the two retaining clips.

13.

Carefully release spring tension so the spring covers the two retaining clips.

I

added a couple drops of oil to the firing pin spring before installing it in the

slide. I installed the assembly into

the slide. I used a small punch to

push down on the rear of the sleeve so I could install the slide cap.

Polishing the Striker

Before

I installed the new sleeve I polished the sear surface.

This had tooling marks from the factory.

I first polished with an 800-grit stick from my

Boride Engineered Abrasives Gunsmith Action Kit,

These stones use oil as the cutting and

cleaning agent.

I

finished polishing with

Brownells Extra Fine Ceramic Stone.

This makes the surface mirror smooth.

After I installed the striker I place some

Brownells Action Lube Plus on the striker sear surface and on the sear in

the frame.

Summary

I am very pleased with how this gun came out.

Now time will tell how durable this coating is and how long it will last.

Addemdum

I

purchased a used

Viridian red laser from ebay which fit the pistol perfectly.

The red dot was nice and bright and was easy to adjust to the sights.

Because it was used it didnít come with any tools, but I used a TORX T6

for the mounting screws and a 0.050 hex wrench to adjust the laser.

This sight adds very little weight to the pistol but makes it easier to

use.

Appendix A:

Polymer Melting and Mold Temperatures

|

MATERIAL

|

MELT TEMP RANGE (℃)

|

MOULD TEMP RANGE (℃)

|

MELT TEMP RANGE (℉)

|

MOULD TEMP RANGE (℉)

|

|

ABS

|

190-270

|

40-80

|

374-518

|

104-176

|

|

ABS/PC ALLOY

|

245-265

|

40-80

|

473-509

|

104-176

|

|

ACETAL

|

180-210

|

50-120

|

356-410

|

122-248

|

|

ACRYLIC

|

220-250

|

50-80

|

428-482

|

122-176

|

|

CAB

|

170-240

|

40-50

|

338-464

|

104-122

|

|

HDPE

|

210-270

|

20-60

|

410-518

|

68-140

|

|

LDPE

|

180-240

|

20-60

|

356-464

|

68-140

|

|

NYLON 6

|

230-290

|

40-90

|

446-554

|

104-194

|

|

NYLON 6 (30% GF)

|

250-290

|

50-90

|

482-554

|

122-194

|

|

NYLON 6/6

|

270-300

|

40-90

|

518-572

|

104-194

|

|

NYLON 6/6 (33% GF)

|

280-300

|

40-90

|

536-572

|

104-194

|

|

NYLON 11

|

220-250

|

40-110

|

428-482

|

104-230

|

|

NYLON 12

|

190-200

|

40-110

|

374-392

|

104-230

|

|

PEEK

|

350-390

|

120-160

|

662-734

|

248-320

|

|

POLYCARBONATE

|

280-320

|

85-120

|

536-608

|

185-248

|

|

POLYESTER PBT

|

240-275

|

60-90

|

464-527

|

140-194

|

|

PET (SEMI CRYSTALLINE)

|

260-280

|

20-30

|

500-536

|

68-86

|

|

PET (AMORPHOUS)

|

260-280

|

20-30

|

500-536

|

68-86

|

|

POLYPROPYLENE (COPOLYMER)

|

200-280

|

30-80

|

392-536

|

86-176

|

|

POLYPROPYLENE (HOMOPOLYMER)

|

200-280

|

30-80

|

392-536

|

86-176

|

|

POLYPROPYLENE (30% TALC FILLED)

|

240-290

|

30-50

|

464-554

|

86-122

|

|

POLYPROPYLENE (30% GF)

|

250-290

|

40-80

|

482-554

|

104-176

|

|

POLYSTYRENE

|

170-280

|

30-60

|

338-536

|

86-140

|

|

POLYSTYRENE (30% GF)

|

250-290

|

40-80

|

482-554

|

104-176

|

|

PVC P

|

170-190

|

20-40

|

338-374

|

68-104

|

|

PVC U

|

160-210

|

20-60

|

320-410

|

68-140

|

|

SAN

|

200-260

|

50-85

|

392-500

|

122-185

|

|

SAN (30% GF)

|

250-270

|

50-70

|

482-518

|

122-158

|

|

TPE

|

260-320

|

40-70

|

500-608

|

104-158

|

|