Setting-Up

and Using a Bench Top Drill/Mill for Firearms Applications

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

I’ve always

wanted to do light-duty milling work to my own firearms.

This includes cutting front and rear sight dovetails,

milling the rear of a 1911 slide to accept a low-mount rear

sight, and cutting front cocking grooves on the front of a

1911 slide. After

completing this project, all my shooting buddies now want me

to mill dovetails and front cocking grooves in their

pistols! So far

I’m doing it for free under the agreement that I won’t

charge them if they’re willing to accept mistakes while

I’m learning. Although

this article is a bit lengthy, it explains everything I did

to get the results I wanted.

I

didn’t have the money for a heavy-duty floor-stand milling

machine, nor did I think this was necessary.

I also felt some of the mini/micro-mills on the

market weren’t stable or heavy-duty enough for the kind of

work I wanted to do. After

some additional research I settled on the 12 Speed

Drill/Mill Machine (item number 42976-3VGA) from Harbor

Freight Tools. Unfortunately, they no longer sell

this model, but they have other similar models available. I

didn’t have the money for a heavy-duty floor-stand milling

machine, nor did I think this was necessary.

I also felt some of the mini/micro-mills on the

market weren’t stable or heavy-duty enough for the kind of

work I wanted to do. After

some additional research I settled on the 12 Speed

Drill/Mill Machine (item number 42976-3VGA) from Harbor

Freight Tools. Unfortunately, they no longer sell

this model, but they have other similar models available.

This machine is a combination drill press and vertical milling

machine with a swivel head that fit my budget, but seemed

heavy-duty enough for the stability I needed for my firearms

applications. The

head also raises and lowers on a column to adjust for

different sizes of work stock.

I have found that most multi-purpose devices such as

this perform each function almost, but not quite as well as a

dedicated machine, but more about this later.

Tool

Stand Tool

Stand

Before the machine arrived, I wanted to have a place to mount

it. My local Lowes

hardware center had a Kobalt 4-drawer workbench with pegboard

back (item # 47106) that I decided to use.

After I unpacked the workbench, I discovered that the

bench top was made of fiberboard.

Fiberboard has a tendency to dissolve when it gets wet,

and I knew that milling required using cutting oil, so I

decided to laminate the top and edges.

There are plenty of how-to instructions on the Internet

for laminating so I won’t go into it here.

However, having carbide-tipped laminate trimming bits

for my router really made the job easy and professional.

Unpacking and Clean-UP

The drill/mill machine arrived by truck packaged in a

wooden crate. It

took about 30 minutes to unpack it from the crate.

After removing the plastic cover, I found the machine

was liberally coated with gooey rust preventative oil (RPO).

It took two cans of brake parts cleaner and numerous

paper towels to get it clean (although I can still put my hand

in places and come away covered with RPO)!

Mounting Mounting

The machine came with a tray used to catch chips and oil.

It had four holes for the mounting bolts, so I used it

as a template to drill the mounting holes in the bench top.

To prevent the tray from moving while positioning the

machine, I drilled and countersunk two holes on either side of

the tray for a #8 wood screw.

This machine is heavy so I had three other people help

to lift it onto the workbench and get it positioned.

Once in position I bolted it in place.

In the process of mounting

the machine, I discovered the tool board on the back of the

workbench interfered with the machine and prevented me from

mounting it on the bench top.

So I cut the horizontal bracket and shelf and

repositioned one vertical bracket to open up one half of the

back of the bench to accommodate the rear of the machine.

I had to add an angle bracket to support the vertical

bracket I moved.

First Trial and Problems

I had ordered some cheap high-speed steel (HSS) milling

bits so now I wanted to try out my machine.

I mounted the machinist vice on the milling table, and

using the metric draw bar, installed the taper and 3-jaw

chuck. I tightened

the draw bar fairly tight; having no experience or knowledge,

which turned out to be a big mistake!

My neighbor, Brad, is a machinist so after helping me

install the machine; he gave me an assignment to make a drill

drift. A drill

drift is a piece of steel bar, about one inch wide that tapers

towards the end. It

is designed to remove a taper from the mill spindle.

I clamped two pieces of steel bar in the vice, chucked

my 1/2” HSS square end mill bit in the 3-jaw chuck, set the

speed to 540, and proceeded to try to mill.

I discovered a number of

problems with this setup.

First, the chuck had 0.003” run out, so I wouldn’t

be using it to mill gun parts.

Second, if I cut too deeply in the steel, the bit would

chatter which caused the swivel head and column to rotate and

the chuck to fall off the taper!

Hmmm, this is not good and would need to be fixed!

Finally, since I tightened the drawbar so tightly I

couldn’t get the taper out of the spindle!

So much for sending an amateur out to do a

professional’s job!

Preventing Head and Column

Swivel

My solution to preventing the head and column swivel was

to install some setscrews.

The machine head is mounded on a hardened steel column

that allows it to swivel.

It is held in place with a handle that squeezes the

head casting around the column to keep it from moving.

The base of the column has a bar with teeth mounted on

the side to allow the head to be raised or lowered.

This is also locked by a handle that squeezes the base

casting around the column.

When my milling bit chattered in the steel, the head

was rotating on the column, and the column was rotating in the

base, even though the handles were locked.

I swiveled the head all the

way to the left, a position I felt I would not be using, and

drilled a hole completely through the head casting and column

of appropriate diameter for tapping a 3/8”–16 thread.

The column was only surface hardened, so after breaking

through the hard surface the drill bit cut easily.

I then tapped the 3/8”–16 threads through the

casting and column. I

positioned the head to where I felt I would do most of my

milling work and drilled a detent in the column through the

threaded hole, being careful not to damage the threads.

Then I installed a 3/8”–16 allen-head setscrew to

hold the head in place. This

plus the handle prevents the head from rotating.

I then raised the head all

the way up as far as it would go, and drilled a hole through

the base casting and column.

I also threaded this hole for a 3/8”–16 set screw.

I lowered the head and drilled a detent in the column

for the height at which I would be doing most of my milling

work and installed the setscrew.

The setscrew and handle now keep the column from

rotating in the base.

Bigger Problem

My next problem was not being able to remove the taper

with the 3-jaw chuck. My

over-tightening of the draw bar caused this.

I enlisted Brad's help and we pounded on the draw bar

trying to get the taper out of the spindle.

All we succeeded in doing was to remove the spindle

from the machine, bearings and all!

The spindle had an opening for the drill drift, but

that was filled with the draw bar.

I decided I could sacrifice the draw bar and order

another one if necessary, so I installed a 1/4“ HSS milling

bit in my small bench top drill press and milled through the

draw bar through the drill drift opening.

I left just enough of the draw bar showing so that we

could get a drill drift in there, and after some radical

pounding with a heavy ball peen hammer, we succeeded in

breaking loose the taper from the spindle.

It was easy enough to press

the spindle back in place by pulling down on the drill press

handle with the spindle resting flat against a piece of wood.

To keep the spindle from coming out again I degreased

the outside of the bottom bearing and inside of the casting

and reinstalled it with a little Loctite 609 green.

609 is used for

press-fit assemblies.

My

First Milling Instruction My

First Milling Instruction

Brad sat me down and we spoke of milling things.

He patiently explained how the taper worked, and what

the draw bar was for. The

spindle has a taper, which is used to install cutting

attachments such as the 3-jaw chuck. There are different types

of tapers; this machine has a Morris #2 (M2) taper.

The 3-jaw chuck and taper should be installed by

quickly “popping” the assembly in place in the spindle.

It should NOT be installed with the draw bar.

The chuck is used for drilling, not milling, and the

downward pressure of the drilling action holds the taper in

place. To remove

the taper, lower the spindle until the drill drift opening is

visible, insert the drill drift and hit it with a mallet.

The chuck and taper assembly should drop in your hand

after only a moderate tap on the drill drift.

Milling

bits should be attached to the spindle using a collet.

A collet is a split cone with a hole in the middle to

accept a milling bit. The

angle of the cone matches the taper in the spindle.

The rear of the collet is threaded to accept the draw

bar. The collet is

threaded onto the draw bar, the shank of the bit is inserted

into the bottom of the collet, and the entire assembly is

inserted into the spindle.

A nut and washer is then attached to the top of the

draw bar. When

this nut is gently tightened it “draws” the collet up into

the taper, which squeezes the fingers of the collet to hold

the bit tightly in place.

The draw bar should be snug, not tight, so that

loosening the nut and rapping the top with a mallet can easily

remove it. Milling

bits should be attached to the spindle using a collet.

A collet is a split cone with a hole in the middle to

accept a milling bit. The

angle of the cone matches the taper in the spindle.

The rear of the collet is threaded to accept the draw

bar. The collet is

threaded onto the draw bar, the shank of the bit is inserted

into the bottom of the collet, and the entire assembly is

inserted into the spindle.

A nut and washer is then attached to the top of the

draw bar. When

this nut is gently tightened it “draws” the collet up into

the taper, which squeezes the fingers of the collet to hold

the bit tightly in place.

The draw bar should be snug, not tight, so that

loosening the nut and rapping the top with a mallet can easily

remove it.

Collets

Ok, back to the Internet to find the appropriate collets

for my M2 taper. My

search engine brought up the Little

Machine Shop,

which specializes in providing tools for mini/micro/bench top

machines. I

purchased their set of M2 Collets (item #1752).

This set comes with seven collets in sizes 1/8",

3/16", 1/4", 5/16", 3/8", 7/16", and

1/2", which I felt would be all that I needed for my

work.

Draw Bar

Remember that I damaged the original metric draw bar that

came with the machine while removing my over-tightened taper.

The new collets required a 3/8”-16 draw bar, so I

really didn’t have to replace the metric one.

The original draw bar had an M10 threaded end about

1/2” long attached to a narrow shank about 11” long.

The end of the shank was threaded to accept a nut.

The M10 end was threaded into the taper; the shank went

through the length of the spindle, and a metric nut was

affixed to the top of the draw bar on top of the spindle.

I fabricated a new drawbar by

cutting off 1/2“ of threaded end from a 3/8”-16 bolt, then

drilling out the center to accept a 12” piece of 1/4“-20

threaded rod. I

tack welded the threaded rod into the bolt end, and viola I

had an acceptable draw bar.

The threaded rod wasn’t exactly perfectly centered or

straight, but the hole in the spindle was wide enough to

accommodate my sloppy work.

I also discovered that a standard 1/4“ flat washer

was too wide to use with my homemade draw bar.

When I pulled down on the chuck feed lever the washer

got caught on the pulley.

So I reduced the diameter of the washer so it would fit

inside the pulley when the chuck was lowered.

To remove the draw bar and

collet from the taper, I took a 2” x 2” square piece of

oak and drilled a hole halfway through just wide enough for

the draw bar nut. To

remove the draw bar, I first fix the chuck with the chuck

fixing lever; this prevents the spindle from moving down when

I hit the piece of wood. I

unscrew the draw bar nut until it is all the way to the top of

the draw bar and covering the top threads.

I place the wooden block over the nut and rap it with a

rubber mallet. It

should only take a moderate hit to loosen the taper.

I make sure to hold my hand under the bit to prevent it

from falling out and striking the table.

This can damage both the table and the bit.

Dial Indicators

Milling is a precise operation that requires exact

measurements, especially when working on firearms.

As well as being able to take precise measurements, you

also need to be able to “do the math.”

The math I’m talking about is adding and subtracting

of fractions, converting fractions to decimals, and some basic

geometry of angles. My

first set of precision tools included a dial indicator, travel

indicator, and adjustable magnetic base.

These are available from Little

Machine Shop for a very reasonable price.

You can also find these items on ebay.

Using the dial indicators is easy if you remember that

you need a fixed, non-moveable point of reference, and a

moveable point of reference.

Another

tool I needed was a set of parallels.

These bars are milled perfectly flat and square and are

used to ensure the work is mounted in the vice perfectly

square and level.

Measuring Level and Run

Out

The first thing I wanted to measure was the accuracy of

the setup of the machine.

First I measured run out on both the chuck and collets.

The chuck had 0.003” run out (±

0.0015”), but the collets had 0.0” of run out. This

will be great for milling!

I measured this by placing the magnetic base on the

cross-slide table and touching the dial indicator to a bit

mounted in either the chuck or collet, then I rotated the

spindle to read the indicator.

Next I measured how level the

cross-slide table was. I

mounted the magnetic base to the non-moveable base of the

machine and touched the tip of the dial indicator to the

tabletop. I moved

the table back and forth and side to side and the dial

indicator stayed at 0. Well,

everything is setup correctly, but I’m still not ready to

mill yet.

Machinist’s

Swivel Vice Machinist’s

Swivel Vice

The machine came with a 70o machinist’s

swivel vice, which means I can rotate it ±70o

from center. The

jaws of a machinist’s vice are supposed to be perfectly flat

and parallel, and the base between the jaws is also supposed

to be flat and square to the jaws.

I mounted the vice to the cross-slide table using the

T-bolts provided. In

order to accurately mill a sight dovetail the vice needs to be

perfectly square to the direction of travel of the cross-slide

table. To measure

this I cut a 3” piece of 3/8” steel rod which I mounted in

the 3/8” collet and put in the spindle.

I then attached the dial indicator to this rod using

the attachment from the magnetic base.

The tip of the dial indicator rides along the inside

edge of the fixed side of the vice.

I moved the cross-slide table parallel with the vice

jaws and rotated the vice until the dial indicator read 0 for

the entire width of the vice.

End Mills

We’re just about ready to begin milling, but first we

need to “tool up” with the appropriate milling bits.

This machine uses end mills, which are similar to drill

bits but have a different cutting edge.

Standard end mills have either a square end or a round

“ball” end. There

are other end shapes available, such as dovetail, but think of

an end mill as a router bit for metal.

When purchasing end mills,

buy carbide. Carbide

allows you to run your machine faster, they seem to cut

smoother, and they last longer.

Another search on the Internet brought me to Sun

Coast Precision Tools Inc., which has a large selection of

carbide end mills. I

bought a selection of end mills from 3/32” to 1/2“.

Front cocking grooves seem to be either 3/32” or

1/8” so I bought four of each.

I also purchased a selection of HSS dovetail end mills

from Brownells

in order to cut front and rear sight dovetails.

Since these bits are HSS they should not turn above 700

RPM, so when I use these I set my speed to 540.

My First Dovetail Slot Cut

I really didn’t want to practice on a real gun part so

Brad brought me a 5” piece of 3/4“ bar stock.

Machinists will tell you that it takes longer to set up

the work than to do the cut.

Please refer to my article Milling

a Front Sight Dovetail for details on how I measure

and cut a dovetail.

Front Cocking Grooves

I had purchased a used Federal Ordnance 1911 .45 and

wanted to practice my milling on it.

My first project I decided to be front cocking grooves.

I wanted the grooves to be vertical to match the rear

serrations, and I wanted them to be narrow 3/32” instead of

1/8”. First I

leveled and squared the slide in the vice.

I used the correct height parallel to accomplish this,

but checked it with the dial indicator anyway.

I set the rear of the spring tunnel against the edge of

the vice as an index point.

The front cocking grooves can’t be too deep because I

don’t want to weaken the slide, but the edges need to be

sharp enough for the fingers to gain purchase, so I adjusted

the travel limit screw accordingly.

Again, to prevent the bit from breaking I took four

passes with each groove, going just a bit deeper with each

pass. Even so, I

broke one bit and left a mark on one edge of one groove.

After I completed one groove, I used my travel

indicator and moved the work twice the thickness of the bit to

cut the next groove. This

made sure the distance between each groove was the same as the

width of each groove. (I

did this to the slide of one of my friends and my travel

indicator slipped without me noticing it.

The gap between two grooves was just a bit larger than

the other gaps. Lesson

learned: be very

careful. As they

say, “measure twice, cut once.”)

After I cut five grooves, I flipped the slide over and

again set the rear of the spring tunnel against the edge of

the vice. After

ensuring the slide was square and level, I cut the grooves in

the other side. Before

refinishing the gun I polished the tool marks out of the

grooves with 320-grit wet/dry paper wrapped around a

jeweler’s file.

The front cocking grooves can’t be too deep because I

don’t want to weaken the slide, but the edges need to be

sharp enough for the fingers to gain purchase, so I adjusted

the travel limit screw accordingly.

Again, to prevent the bit from breaking I took four

passes with each groove, going just a bit deeper with each

pass. Even so, I

broke one bit and left a mark on one edge of one groove.

After I completed one groove, I used my travel

indicator and moved the work twice the thickness of the bit to

cut the next groove. This

made sure the distance between each groove was the same as the

width of each groove. (I

did this to the slide of one of my friends and my travel

indicator slipped without me noticing it.

The gap between two grooves was just a bit larger than

the other gaps. Lesson

learned: be very

careful. As they

say, “measure twice, cut once.”)

After I cut five grooves, I flipped the slide over and

again set the rear of the spring tunnel against the edge of

the vice. After

ensuring the slide was square and level, I cut the grooves in

the other side. Before

refinishing the gun I polished the tool marks out of the

grooves with 320-grit wet/dry paper wrapped around a

jeweler’s file.

Rear

Sight Rear

Sight

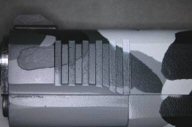

After completing the front grooves, I milled the rear of

the slide to accommodate a low-profile Millet adjustable

sight. I had to

purchase two additional end mill bits for this job; a standard

3/8” dovetail cutter, and a 3/16” round end cutter.

The instruction sheet provided by Millet with their

sight gave all the cutting dimensions.

The round end mill was used to mill a groove on either

side of the slide for the rear sight.

(Yes, I refinished the gun with Dura-Coat in an Urban

Camouflage pattern! You

may laugh or you may sneer, but the work is all mine!)

Conclusion

In spite of what so called “experts” say, you can

perform firearms work with a bench-top milling machine.

The machine must be heavy and stable enough to perform

the precision work necessary for firearms.

Also, you need to have the proper measuring tools to

ensure your work is precisely aligned, and when necessary,

moves a precise amount. There’s

nothing like the satisfaction of doing a job yourself, and

doing it well.

Resources

|