Milling a

Front Sight Dovetail

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

One of the

more advanced procedures I perform to my guns is to cut a

front sight dovetail, and of course, install the

corresponding sight. I purchased a 1911 .45 ACP slide

that didn't have a front sight so I decided to install a

fiber-optic front sight.

Since the slide did not come with any front sight

cuts I had to mill the dovetail.

This sight required a 65o x 0.330 width

x 0.075 depth dovetail.

Before

milling the dovetail, I had to make sure the slide was mounted

exactly perpendicular to the cross-slide table of the mill and

perfectly level so the sight would be straight.

First,

I squared my swivel vise.

I rotated the vise until the dial indicator read

0.000 across the fixed face of the vise.

Next,

I installed the slide in the vise using a parallel.

I put blue tape on the sides to protect the slide

while clamped in the vise.

I ran my dial indicator across the top of the slide

to ensure it was perfectly level.

When

I cut a dovetail slot I cut out the center of the slot first

with a square end mill, then cut the angles with the

dovetail cutter.

This is called a pilot slot. The dovetail cutter is made of high speed steel (HSS) so it

is best not to load up the teeth by using it to cut the

entire dovetail. Ok, now it is time for some

higher math.

I knew

angle A was 65o, the depth B was 0.075, and the

width C was 0.330. I

needed to find the length of line D so I could subtract it

twice from line C to find the width of the cut.

I found that value using this formula:

C - (2 * B

/ tangent(A)) = cut width.

Substituting the values for the letters gave me:

0.330 - (2

* 0.075 / tangent(65)) = 0.260

(I did this with the scientific view of the calculator

that came with my computer software.

I have since created an Excel spreadsheet to perform

these calculations. Download

a copy by right-clicking here.)

Well, this

worked out to be 0.26 which is a hair over 1/4.

Since I had a 1/4 carbide end mill this is what I

used to make the initial cut.

Now

I needed to know where to position the center of the end

mill. I took my

calipers and measured the length of the sight, which was

0.5. Since

the base was in the center of the sight, the midpoint was

0.25.

I installed the 1/4 end mill bit in my mill.

I used a 0.010 feeler gauge and moved the front of

the slide until it was 0.010 away from the bit.

I set up the travel indicator and moved the piece

0.010 (thickness of feeler gauge) + 0.25 (distance to

middle of sight dovetail) + 0.125 (half the thickness of

the bit).

I added an additional 0.005 so the sight would be

back from the edge of the slide just a bit.

So I moved the bit a total of 0.010 + 0.25 +

0.125 + 0.005 = 0.39.

I had now correctly positioned the bit to cut the pilot

slot.

Since the depth of the sight dovetail was 0.075 I

adjusted my depth of cut to 0.075 below the top of the

slide.

First, I positioned the slide under the center of the

bit, and then using a 0.010 feeler gauge moved the bit

down until it was touching the gauge.

I positioned the travel indicator so the point was on

the bottom of the spindle.

Then, I adjusted the depth of the spindle down

0.010 (thickness of feeler gauge) + 0.075 (depth of

sight dovetail).

Notice in the photo above the dial indicator

reads 0.085.

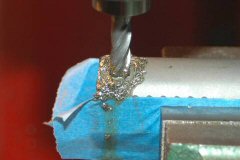

Ok, so now I was ready to cut the pilot slot.

I was using a carbide bit so I set the spindle speed

to 1500 RPM, but I didnt want

to break my bit so I moved the cross-slide table fairly

slowly and used plenty of

cutting oil.

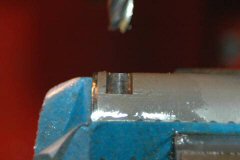

I replaced

the square end mill with a 65o x 0.330

HSS dovetail cutter. I

positioned the work and lowered the bit so one tooth was

touching the bottom of the pilot slot, then locked the spindle

shaft at that depth. The

instructions for the bit say to never go above 700 RPM, so I

set the spindle speed to 540 RPM.

Again using plenty of cutting oil, I made a slow single

pass to finish cutting the dovetail.

I cleaned off all the cutting oil from the slide by

spraying thoroughly with brake parts cleaner.

The front sight had a raised lip all around the

underside of the base so I set a piece of 600 grit paper on

a flat surface and rubbed the bottom of the sight until it

was flat.

I

took my sight base file and carefully filed the rear of the

dovetail cut in the slide until the sight would slide on

easily about 1/4 of the way into the dovetail.

I took only 3 or 4 light strokes with the file then

tried the sight. Once

I got the sight started, I set it in place with a brass punch.

To complete the sight installation I removed the sight,

cleaned the sight base and dovetail with Acetone, then put a

drop of green Loctite 609 on the dovetail and re-installed the

sight. The Loctite

ensures the sight stays in place.

Here

I am tapping in the front sight. I used a brass punch so

I wouldn't mar the sight. I used regular bore copper

cleaner to clean off the brass residue.

Here is the completed front

sight installation. Nice and clean, and the sight fits

tightly in the dovetail. This sight will never come off

during shooting.

Now

I needed to install the colored optic fiber rod into the front

sight.

I had a choice of two colors, red or green.

I have never liked red sights because they seem to

disappear into the background, so I chose the green rod.

I cut the green rod and inserted it into the hole in

the sight leaving a bit exposed on each end.

I took a cigarette lighter and heated each end until it

ballooned thereby locking the rod into the sight. In the

photo above the slide has been parkerized. I

installed the fiber optic rod after I finished the slide.

That

green fiber optic rod really gathers the light and helps me

with quick target acquisition. The first time I used

this gun in a match I had no misses. Not bad for a

kitchen table gunsmith.

|