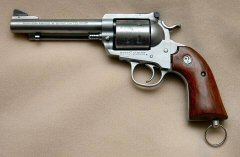

Adding a Lanyard Ring to a Ruger® Blackhawk®

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

The

lanyard and lanyard ring have been around almost as long as

handguns themselves. Originally,

mounted cavalry used the lanyard to prevent the soldier from

losing his gun. The

lanyard was looped around the waist or shoulder and

connected to a ring mounted to the bottom of the grip frame.

Many manufacturers who produced revolvers for the

military often included a lanyard ring per government

specification. Colt,

being one such manufacturer, produced many of its guns for

the military with lanyard rings including black powder

revolvers, Single Action Army models, and the 1911.

The early 1911 models produced for the military had a

lanyard ring on the bottom of the main spring housing.

Modern shooters are rediscovering the value of the

lanyard so some after-market 1911 parts makers are producing

main spring housings with a lanyard ring.

The

single action revolver is the perfect gun for carrying in

the woods while hunting or backpacking.

However, the gun can still work itself free in heavy

brush even when carried in a well-secured holster.

A lanyard connected to a belt and lanyard ring can

help prevent losing, and perhaps never recovering, a

valuable firearm. I

have a stainless steel Ruger® Bisley Blackhawk® with a 5

1/2“ barrel that I plan to carry as a backup when I go hog

hunting. I

certainly don’t want to risk losing it in the woods, so I

installed a lanyard ring.

One

of the easiest ways to install a lanyard ring to a revolver

is to attach a sling swivel stud to the bottom of the grip

frame. First, I

made sure my revolver was not loaded, then disassembled it

enough to remove the grip frame.

(Refer to my article

Ruger

Single-Action Revolver Disassembly/Reassembly and Spring

Replacement.) I

removed all loose parts from the grip frame, i.e. hammer

strut, mainspring, and mainspring seat, trigger return

spring and pivot pin and set them aside.

I

purchased a package of Uncle Mike’s 7/8” nickel machine

screw sling swivel studs.

The stem of these studs is not threaded all the way to

the top, so I used a 10-32 die to finish cutting threads to

the base of a stud.

I

put the grip frame upside down in my machinist vise and used a

#21 drill to drill a hole.

The location of the hole is not critical, so exact

measurement is not necessary.

However, I did locate the hole towards the rear of the

grip frame, and centered it on the width by eye.

I

then used a 10-32 tap to thread the hole.

I made sure to use plenty of cutting oil to lubricate

the tap. I always

use my drill press and vise grips to ensure the tap starts

straight. I

tighten the chuck just enough to keep the tap straight, but

still allow it to rotate freely. After

threading the hole, I thoroughly cleaned off all traces of oil

and cutting chips.

I

cut the stem of the stud to 1/4” in length using a cut off

wheel and my high-speed rotary tool.

I put a drop of blue thread-locker on the threads, then

installed the stud. I

had to install a flat washer because the threads were cut in

such a way that the hole in the stud did not properly align.

With the flat washer in place, the hole in the stud now

aligned parallel to the frame.

To

finish my lanyard ring installation, I installed a one inch

split key ring into the hole in the sling swivel stud.

I can now attach a spring hook to the ring, which in

turn is connected to a lanyard.

Typically I use a length of 1 1/2“ nylon webbing with

a plastic spring hook looped over my left shoulder. The

plastic spring hook connects to the lanyard ring.

I got this idea from Junior Doughty’s excellent web

site The

Frugal Outdoorsman. In

fact, you can purchase ready-made slings from Junior, just

click on the link.

|