Adding Camouflage Using Hydrographics

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Introduction

This year during the last week of January my mom turned 90,

so the entire family got together to celebrate this happy

occasion. Everyone in the family knows that I am a “gun

guy” so it was only natural that my 22-year old nephew,

Nathan, came to me with a gun question. He wanted to go

duck hunting with some of his friends in the fall and asked

me what shotgun to buy. My somewhat glib response was

anything that would go bang and kill a duck! After a brief

moment of confusion he then asked me what brand of shotgun I

would recommend. I told him Remington, Mossburg, Browning,

Winchester – just to name a few – all made fine shotguns; it

would really depend on what he could afford. I made it

clear to him, however, that it’s not the gun that’s

important; it’s the man behind the gun. I once made fun of

a friend for shooting a short, youth model, single shot

.410-gauge shotgun. He never missed with that little gun

and put me in my place by consistently beating me at

shooting clay pigeons! It turns out he grew up on a farm

using that gun since he was a child so he had many years of

practice; and it showed.

I own

three 12-gauge Winchester model 1300 shotguns; one is a

Defender model that I use for three-gun competition, and the

other two are field-grade. So how did I wind up with two

field-grade guns? When I purchased the 1300 Defender I

wanted to use it for turkey hunting so I went down to my

local gun store and found a 1300 12-gauge barrel for $79.

Unfortunately it wouldn’t fit on the Defender because the

Defender had a longer magazine tube. I then found a

field-grade 1300 on

Gunbroker for $179 and won the bid. (I couldn’t believe

no one else bid on it!) Years later I found a complete 1300

field gun receiver also on Gunbroker that did not have a

barrel. I already had the barrel so I purchased the

receiver for $150 knowing that I could sell the complete gun

later. I decided to gift this second gun to Nathan – how

many of us received our first gun as a gift from a father,

uncle, or mentor – but I wanted to prepare it for him for

duck hunting by adding camouflage. There are a number of

methods to camouflage a gun; some good and others not so

good:

|

Method |

Advantages |

Disadvantages |

|

Paint |

Easy to apply, stencils are available for more

realistic patterns, protects from rust and corrosion

|

Permanent, not realistic pattern, can be messy to

apply, any rust left on the gun will continue to

corrode under the paint |

|

Slip-on/wrap around cover |

Not permanent, various patterns, easy to apply and

remove |

Can get in the way of moving parts, sights, and

ejection ports |

|

Tape |

Easy to apply, fits to the form of the gun, not

permanent, can be replaced with different realistic

patterns depending on hunting environment |

Leaves sticky residue |

|

Heat-shrink wrap |

Not permanent, uses heat to shrink the wrapping to

fit shape of gun, realistic patterns, can be

replaced with different patterns |

Time-consuming to remove, does not protect metal

parts from rust if left on

|

I painted

a camouflage pattern on a synthetic stock for my M1A. I

made my own stencils to get the pattern I wanted and used

camouflage spray paint I bought at the hardware store. It

came out looking pretty good, although somewhat WWII-ish,

but that convinced me that painting my own pattern was not

the way to go. Watch the move Shooter with Mark

Wahlberg and notice how he uses camouflage paint and natural

leaves and sticks as stencils to apply a camouflage pattern

to a sniper rifle.

(Photo courtesy StumpJumper)

RusticMan.com and

StumpJumper have great articles for painting a reed

pattern onto a shotgun. Stump has graciously allowed me to

publish his instructions; refer to my article

DIY Camouflage for a Shotgun.

Hydrographics

A very popular method for adding camouflage to a gun is

using hydrographics, sometimes called liquid printing, water

printing, or water transfer imaging. Many firearms

manufacturers are using this method to enhance their factory

guns. A film is produced by printing a camouflage pattern

onto a water-soluble backing. A piece of film is cut to the

desired size and placed into a tank of water which causes

the backing to dissolve leaving the pattern floating on top

of the water. A chemical activator is sprayed onto the

pattern which causes the ink to turn to liquid, then the

prepared part is dipped into the liquefied pattern causing

it to wrap itself around the part. After the now

camouflaged part is dried it is coated with a clear coat to

protect the finish. This camouflage method is permanent,

but the patterns are very realistic, and the clear coat

protects the gun so you never have to keep the outside oiled

or worry about rust. One major advantage to this method is

that you are not limited to camouflage patterns. I’ve seen

guns finished with skulls, flames, carbon fiber, wood grain,

pretty much any pattern you can think of.

My first

Winchester 1300 field gun I sent away to

Bell and Carlson to have them apply a Realtree®

Hardwoods Green hydrographics camouflage pattern for turkey

hunting. The gun came out beautifully as you can see from

the above photo. I sent them the gun complete with scope

mount and scope and they coated everything. Unfortunately

they no longer offer this service. Being an amateur

gunsmith and willing to try and learn new things I thought

if I could get the materials I could probably do this

myself.

I did

some research on the Internet and found a company that sells

a do-it-yourself hydrographics kit called

MyDipKit. They have many different patterns to choose

from including 58 camouflage patterns. The complete kit

comes with four spray cans; primer, base coat color,

activator, and clear coat finish, latex gloves, a brown

coarse scrub pad, mask, and a sheet of the pattern film.

They have three different kits to choose from; I chose the

“designer” kit which comes with 2.5 square meters of film.

This provided plenty of film to cover the gun and enough to

practice, learn, and make mistakes.

(Pattern courtesy MyDipKit)

For

ducking hunting in a marsh environment I chose the Vzion

Outdoors® Boggy Vision ® pattern shown in the figure above.

I chose this pattern because duck hunting usually takes

place in a marshland environment. If you look closely at

the above pattern you can see there is a right-side-up,

which meant I couldn’t cover both sides of a part with one

dip because one side would have the pattern upside down.

Would ducks notice the difference…of course not, but I

would, so that meant I would have to do half of each part at

a time.

Disassembling the Gun

First I

completely disassembled the gun into the major components I

planned to dip. The magazine tube will be masked off since

it will not receive any camouflage. The ring at the bottom

right is the slide arm cap. This cap holds the fore end

onto the slide arm extension.

Cutting

the Film

I then

cut out the sheets I needed to cover each part of the gun.

There needed to be enough film to cover the piece with some

leftover. Per the instructions I used masking tape to

create a frame, then cut out around the frame. I put a

piece of white poster board behind the film when laying it

out for cutting to make it easier to see. My cutting table

is brown which made the film very difficult to see; it is

camouflage after all! The film was not wide enough to cover

the entire barrel so I laid the barrel onto the film at an

angle so I could cut one long piece.

Practicing and Learning

So now I had a lot film leftover, so I cut some 4x4 squares

to use for practice. MyDipKit has a number of excellent

videos that I studied thoroughly before attempting this

project. I also did a search on YouTube for “hydrographics”

and found many helpful videos there. The last thing I

wanted to do was mess up Nathan’s gun so I performed some

practice dips. MyDipKit sells some plastic forms for

testing and displaying your work, but I didn’t want to spend

the $25, so I decided to perfect my skills using empty cat

food cans. These cans are small and round which gave me

plenty of opportunity to practice; and besides they were

free!

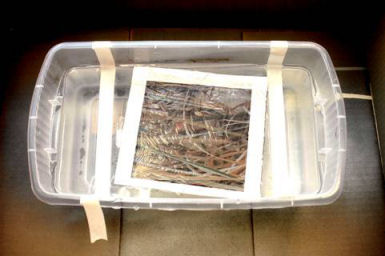

A quick

trip to Walmart got me a large plastic storage bin, masking

tape – both 0.7” and 1.4” wide, and some Play-Doh. The

storage bin was a Sterilite® 41-quart under-bed box model

#1860 that measured 36” x 17” x 6”. Although it is only

6-inches deep, because I’m doing only half of a part at a

time it should be ok to use for my dipping tank.

The

process was pretty straight forward:

Step 1. Prepare

the Part

a. Clean

thoroughly and remove any grease and oil

b. Mask

off any areas not to be covered.

c. Scuff

with the included scrub pad. This will remove any finish

and allow the primer paint to stick. . The blued parts I

scuffed with 120-grit sand paper, then degreased with

acetone. The smooth areas of the wood I sanded with

220-grit sand paper but I did not touch the checkering.

d. Spray

with a light coat of the included gray primer and allow to

dry for 1 to 2 hours. Apply the base coat of paint within

24 hours.

e. Lightly

scuff and apply the base coat of spray paint. Multiple

light coats are better than one heavy coat which could run.

Allow to dry for 1 to 2 hours.

f. Make

sure you have some method of holding the part for dipping

that won’t interfere with the surface to be covered. For

large, square items like plastic lids you can install a

masking-tape handle on the inside. Different sizes of

wooden dowel make great handles.

Step 2. Set

Up the Dipping Container

a. The

dipping container should be large enough to allow the film

to expand, and deep enough to submerge the entire part.

There should be about one inch of space around the film. It

is important that the film be allowed to expand, otherwise

you will get air bubbles.

b. Fill

the container with lukewarm water until it is about one-inch

below the top. The water should be between 70 and 80

degrees; measure with a cooking thermometer.

c. If

the container is larger than the film piece, add a

masking-tape border to the top of the water about one-inch

larger than the film. Use a piece of paper cut to the same

size as the film to create the border.

Step 3. Prepare

the Film – The film has a water-soluble backing so do not

get the film wet or expose to a high-humidity environment.

Keep any unused film in the shipping tube it came with.

a. Roll

out the film with the ink-side up.

b. Lay

the part to be dipped onto the film.

c. Layout

a masking tape frame onto the film leaving enough film so

the part will be covered when dipped.

d. Cut

out around the masking-tape frame

Step 4. Processing

– Here is where the fun begins and where the most problems

can occur

a. Cut

slits in the masking-tape frame to allow the film to

expand. Cut each corner and the center of each side. For

long pieces cut multiple slits. Cut completely through the

tape and into the film.

b. Holding

the film by each corner and folded up like a sling, slowly

immerse it into the warm water. Do NOT get any water onto

the ink side of the film or it will not stick to the part.

The film should float on top of the water.

c. Wait

60 seconds to allow the backing to dissolve; use a timer to

time accurately.

d. Spray

a thin coat of activator evenly onto the film. The film

will start to expand, but won’t expand any farther than the

edges of the dipping tank or masking-tape border which you

laid on top of the water. After about 15 to 20 seconds the

film will take on a glossy appearance and turn to liquid

ink. Here is where most people have problems because they

either spray on too much activator, or don’t apply it

evenly.

Step 5.

Immerse

the Part

a. Wear

vinyl or latex gloves as the ink will get onto your hands.

b. Hold

the part at a 30-40 degree angle and slowly submerge the

part into the liquid ink. The angle will prevent

air-bubbles from forming.

c. Once

the part is completely submerged give it a gentle shake to

remove any excess liquid ink. Don’t touch the sides or

bottom of the tank as the liquid ink could rub off.

d. Remove

it from the water and allow it to sit for 60 to 90 seconds.

Step 6.

Rinse the

Part

a. Do

not touch or rub any part that has been covered or it will

come off.

b. After

the part has been dipped rinse with warm or hot running

water until the covered part is no longer glossy in

appearance.

c. The

part must be completely free of any residue left from the

printing process, otherwise the clear-coat finish will not

adhere properly. Any area that still appears glossy can be

re-rinsed.

d. Allow

to air dry thoroughly, although I found a hair dryer helps

to speed up the drying process.

Step 7.

Apply Top

Coat

a. Apply

the included clear-coat finish. Spray with light, even

passes.

b. Apply

multiple thin coats to achieve the desired appearance.

c. Allow

to dry before using. Clear coat finishes harden over time

and should be completely cured after about 14 days.

Following

the above process I first removed the excess glue from the

can where the label was attached. I used some acetone which

also removed much of the paint. I then sprayed the can with

the gray primer and let it dry for 1 hour. After the primer

dried I sprayed the can with the tan base coat. Although

the can said tan, it was very light, more of a beige. This

base coat provides the background color where the pattern

would otherwise be clear. By changing the color of the base

coat you can change the color of the pattern. MyDipKit

doesn’t sell a green paint, but their instructions state

that a good quality automotive paint will work. Someday I

will purchase some green automotive touch-up spray paint and

try this pattern with green just to see how it looks.

I

“borrowed” one of my wife’s small storage bins and used it

as a dipping tank. I followed the process for my test can

and I was very impressed with the result as you can see from

the photo.

Ok, that

came out pretty good. Now I wanted to try it with a small

part. I decided to try it with the magazine end cap. I

screwed the cap onto a wooded dowel to use as a

painting/dipping tool. The dowel also prevented overspray

and film from getting inside the cap. After spraying with

primer and base coat I scratched off a mark so I would know

where the top of the cap was after tightening it on the

gun. I prepared the film as before and dipped the prepared

cap. As you can see from the above photo it came out very

nice once again. I discovered through trial and error that

if the piece of film is too large it will build up on the

part. However, it won’t stick to itself so the excess comes

right off during the rinsing process.

I decided

to completely assemble the slide arm in order to get a

contiguous pattern on both the wooden forearm and slide arm

cap. I masked the slide arms and top of the slide arm tube

with masking tape, and used a wooden dowel covered with

masking tape to fill the front hole. The dowel allows me to

hold the assembly while dipping. I had to dip the slide arm

assembly twice because it didn’t cover the top edges the

first time. The second time I dipped it half-way into the

ink then rolled it to cover the other half. This ensured

everything was completely covered.

As stated

before I masked and covered half of the butt stock and

receiver at a time because I didn’t want half of the pattern

to be upside down. The results are shown in the above

photo.

The

barrel presented a little bit more of a challenge. Since

the film was not wide enough to cover the barrel in one

piece, I laid the barrel on the film at an angle and cut out

the piece I needed. That left a lot of wasted film on the

corners of the diagonal cut.

I removed

the fiber-optic bead, plugged the barrel with a tapered

wooden dowel, and plugged the chamber with a cork. I used

masking tape to mask off the end of the choke tube and the

end of the barrel where it fit into the receiver. The

masking tape also helped hold the dowel and cork in place.

I then went over the barrel with 120-grit sand paper, then

cleaned it with acetone to remove all grease and sanding

residue.

When the

film was ready I dipped the right side of the barrel

half-way into the film, then rotated it to the left side and

finished dipping. I took the barrel outside and used my

garden hose to rinse it off. Unfortunately I had some gaps

on the right side, probably because I didn’t move the barrel

at the same time that I rotated it. Still, it came out

pretty good.

Here is

the finished shotgun ready for duck season. This was my

first attempt at hydrographics so it’s not perfect, but as

my friend Chilli Ron said, it's a tool for hunting, not a

work of art! Happy birthday Nathan.

|