Refinishing a 100 Year Old Winchester 97 Shotgun

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Introduction

I recently modified a 100 year old Winchester model 1897 for

competition (refer to my article

Modifying a Winchester 97 for Competition). This

gun was originally built in 1907 which made it over 100

years old, and functioned flawlessly during a Wild Bunch

Match. Some people may balk at the fact that I made changes

to this old gun, but for me this is a shooter, not a

collectable wall-hanger, so I had no problem making those

changes.

As with

many original Winchester 97’s that I’ve seen, most of the

bluing had worn off and whatever was left had taken on a

brown patina. Also, due to years of poor care, the exterior

metal was pitted from rust. I decided I wanted to refinish

this old gun and make it look as close to brand new as I

could get. Re-bluing the metal will also protect it from

further corrosion.

Refinishing Plan

This was probably my most ambitious project to date. I have

refinished stocks (refer to my article

Modernizing a Winchester 37) and cold-blued

receivers (refer to my article

Restoring a Ted Williams Model 100 .30-30), and I

have Parkerized complete guns (refer to my article

Reactivating a Springfield 1903-A3 Drill Rifle), but

this will be the first time I refinish an entire blued gun.

My refinishing plan was as follows:

-

Remove all the old external bluing

-

Polish the metal

-

Re-blue the exterior metal surfaces with

Dicropan IM®

-

Strip

the wood

-

Cover

the gray epoxy seam where I repaired the stock and

action slide handle

-

Finish the wood with

Birchwood Casey® Tru-Oil®.

Dicropan

IM® is the same bluing process I used to refinish a Ruger

.45 ACP cylinder (refer to my article

Refinishing a .45 ACP Conversion Cylinder with Brownells

Dicropan IM®). It is a rust bluing process which is

much more durable than cold bluing and when done correctly

the results are beautiful.

Practice

Before working on the gun itself I practiced on the piece I

had left over from shortening the barrel. Since this piece

of barrel had the same finish problems as the rest of the

gun I could work out my metal refinishing process.

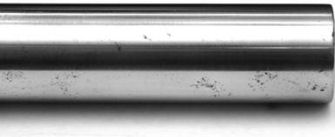

I first

polished the barrel with 220-grit wet/dry sand paper. This

removed the old bluing but left behind pits that I couldn’t

remove as you can see from the above photo. I used a small

wire brush and my Dremel tool to remove the corrosion buried

in the pits. I then polished with 320-grit paper, then

finished with 400-grit paper. I final polished with

400-grit Polish-O-Ray I purchased from Brownells

#080-505-400 and a felt buffing wheel attached to a hand

drill. The Dicropan IM® instructions recommend this as the

final polish prior to bluing.

I

performed the Dicropan IM® process 5 times to get the

darkness of bluing I wanted. The barrel section came out

looking beautiful and the bluing was nice and even. The

above photo appears to have streaks, but this was caused by

the lighting I used for the photo.

Although

time-consuming, the Dicropan IM® bluing process is pretty

easy, and as mentioned before, the results are beautiful and

durable (the following steps are a summary; refer to the

Dicropan IM® instructions for the complete process):

Step 1.

Polish

the metal

Step

2.

Degrease

with acetone or Brownells TCE

Step 3.

Immerse

in boiling water for 5-minutes

Step 4.

Card off

any rust

Step 5.

Apply

coat of Dicropan IM® for 60-seconds; throw away the

applicator

Step 6.

Immerse

in boiling water for 15-minutes

Step 7.

Remove

from water and allow to dry

Step 8.

Card off

any rust; throw away the degreased steel wool used for

carding

Step 9.

Apply

coat of Dicropan IM® for 60-seconds

Step 10.

Immerse

in boiling water for 5-minutes

Step 11.

Remove

from water and allow to dry

Step 12.

Card off

any rust with a second piece of degreased steel wool

Step 13.

Repeat

Steps 9-12 until desired color is achieved

Step 14.

Coat with

a water-displacing oil

Refinishing the Metal

I completely disassembled the shotgun into its major

components. I unscrewed the action slide sleeve screw cap

with a special spanner wrench I purchased from Brownells

#080-548-012 and removed the action slide handle from

the action slide.

I started

with the magazine tube and action slide. I performed the

metal preparation as described in the practice section

above. I did not refinish the entire action slide; only the

arm that engages the carrier. The arm has the Winchester

name and model stamped into the metal and is the only part

of the action slide that is visible. I taped a wooden plug

into the threaded end of the magazine tube, and a rubber

cork into the plug end. The wooden plug was long enough so

I could use it as a handle and not touch the metal. After

the parts were blued I thoroughly cleaned and oiled the

insides to remove any rust that had formed from immersing

them in the hot water. The inside of the magazine tube was

already rusted and pitted when I first purchased the gun so

I didn’t want any additional rust to form.

The

magazine tube was too long to fit into any of the pots we

had in the kitchen so I purchased a black iron bluing tank

from Brownells

#082-003-664. This tank was so long that I had to set

it diagonally across the right-rear and front-left burners

of my gas stove. The stove was just barely hot enough to

bring the water up to a slow boil, but that was enough to

refinish the metal parts. For the smaller parts I used a

regular stainless-steel pot.

To

prepare the receiver I first removed all of the small parts

and placed them in plastic bags labeled “L” or “R” so I

wouldn’t get them mixed up. I used a 10-inch mill bastard

file to draw-file the flats to remove most of the pits and

scratches. I then wrapped various grits of wet/dry sand

paper around the file to remove the filing marks and polish

the metal. I started with 220-grit, then 320-grit, then

finished with 400-grit. The rounded areas of the receiver I

shoe-shined with strips of wet/dry sand paper starting with

the 220-grit and finishing with the 400-grit. I had to be

very careful not to damage the serial number on the

receiver. Damaging or altering the serial number is

illegal. Fortunately the serial number and inspector’s mark

were stamped deeper than the pits so they were still clearly

visible. I finished polishing with the 400-grit

Polish-O-Ray and a felt buffing wheel.

The rear

of the receiver that mated with the butt stock had the

deepest pits. This seems to make sense to me since the

shooter’s hand would constantly be in contact with that part

of the receiver leaving body oil behind and causing rust.

You can

see in the above photos that I didn’t remove all of the

pits. Some of them were very deep and I didn’t want to

weaken the receiver by removing too much metal.

Next I

refinished some of the smaller parts:

-

Magazine Band

-

Magazine Plug

-

Trigger Guard Bow

As before

I couldn’t remove all of the pits but the Dicropan IM®

bluing process comes out beautifully dark and even.

Finally I

refinished the barrel assembly. I prepared the metal as

mentioned before. I wore a filter over my nose and mouth so

I wouldn’t get metal and sandpaper bits in my nose and

lungs. I removed the brass bead for polishing, then

replaced it for bluing.

I plugged

the breech and muzzle with wooden dowels, and again used my

long iron bluing tank on my kitchen stove for the heated

water. The Dicropan IM® instructions say to apply the

solution in a “slurry” which seems to give the most even

result. I used cotton balls stuffed into the toe of a nylon

stocking and liberally applied the Dicropan IM®. The barrel

came out dark and even after only five applications.

For small

parts such as pins and screws, the trigger, hammer, and top

of the carrier I cold-blued with

Birchwood Casey® Perma Blue®. I cleaned the part with

acetone then suspended it in the cold-blue solution for just

a couple of seconds. I didn’t have to remove the old bluing

as the Perma Blue® left a deep blue/black finish right over

the old bluing.

Stripping

the Wood

While the

gun was completely disassembled I used

Klean-Strip® KS-3 premium stripper I purchased from my

local home improvement store to remove the old oil and

finish from the butt stock and action slide handle. I

applied three coats of stripper and let each coat stand for

15-minutes before removing. As you can see from the above

photo there are still a couple of dark areas on the wrist

and action slide handle that still have oil from years of

handling. I applied two additional coats of stripper, then

scrubbed the wood with a scrubbing pad and mineral spirits.

After

stripping the wood I steamed out as many dents as I could by

laying a wet towel on the wood and pressing a hot iron to

the towel. I went over the entire butt stock, but couldn’t

remove all of the dents or scratches. Everyone tells me

this gives the stock character! After the wood dried I

sanded it with 600-grit sand paper to remove any “feathers”

raised by the steaming process.

I applied

three coats of

Birchwood Casey® Tru-Oil® allowing each coat to dry for

six hours. I have always liked the smooth, semi-glossy

finish Tru-Oil imparts to the wood as you can see from the

above photo. As mentioned before you can still see some

dents, gouges, and scratches but what do you expect from a

100-year old stock?

Replacing

the Action Slide Stop

About 2

1/2-inches from the end of the magazine tube was a small

piece of metal with two screws. This piece of metal

prevented the magazine tube from coming out of the barrel

assembly too far. My gun had one screw missing so I decided

to replace the entire slide stop. I removed the single

screw and slide stop, drilled out the two holes in the

magazine tube with a #43 drill bit, then tapped each hole

with a 4-40 tap.

I took

two 4-40 hex-head screws and cut the head in half then used

a Dremel cutoff wheel to cut a notch in the top of the

head. I had to cut the heads in half so they would pass

under the barrel when the magazine tube was rotated for

disassembly. I then cut the threaded part so only 1

1/2-threads were left. I then installed them in the

magazine tube holes with Loctite blue. I tested my fix by

loading six dummy shells in the magazine tube to ensure

nothing was binding on the ends of the screws. This was a

very elegant fix; the screws do not contact the barrel when

rotating the magazine tube, and the magazine tube does not

come out too far when disassembling the shotgun.

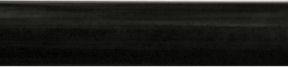

Above is

a photo of the completed restoration project, but it really

doesn’t show the proper beauty of the gun. The metal parts

still have many pits leftover from years of neglect and

rust, but the new bluing will help prevent any additional

rust or corrosion from forming, and it really does make the

gun look beautiful again. A couple of my shooting buddies

asked if it was a Chinese copy, but I told them it was a

restored original Winchester ’97 built in 1907. The bluing

should last for many years and many matches and I can be

proud to show off the work I did to restore this old gun.

I

discovered after some trial and error that the first

application of Dicropan IM® seems to be the most important.

The trick is to use a large applicator and apply a lot of

solution. I tried using large gun cleaning swabs but they

didn’t apply enough solution to get the bluing even.

Eventually I used cotton balls stuffed down into the toe of

a nylon stocking and tied off and cut the top off of the

stocking so I had a nice large swab. This applied a large

amount of bluing solution during the initial application

which meant I only needed to perform the apply/boil/card

process 5 times.

|