Etching With Electrolysis

by Roy

Seifert

Click here to purchase a zip file with this and

all Kitchen Table Gunsmith Articles.

Disclaimer: This

article is for entertainment only and is not to be used in lieu of a

qualified gunsmith. Please

defer all firearms work to a qualified gunsmith.

Any loads mentioned in this article are my loads for my

guns and have been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of these loads,

or use or misuse of this article.

Please note that I am not a

professional gunsmith, just a shooting enthusiast and hobbyist, as well

as a tinkerer. This

article explains work that I performed to my guns without the

assistance of a qualified gunsmith.

Some procedures described in this

article require special tools and cannot/should not be performed

without them.

Warning: Disassembling

and tinkering with your firearm may void the warranty.

I claim no responsibility for use

or misuse of this article. Again,

this article is for entertainment purposes only!

Tools

and firearms are the trademark/service mark or registered trademark of

their respective manufacturers. Click on any

blue text to go to a

product/seller web site.

Introduction

I

have two .45 Ruger Redhawks in my collection which I converted to also shoot .45

ACP with moon clips by thinning the ejector star.

Refer to my articles

Converting a KRH .45 LC Redhawk to shoot .45LC and .45ACP and

Building the Super Redhawk

ďTriple DefenderĒ. Because

I altered the caliber I needed to mark the new caliber somewhere on the barrel.

I thought the best way to add .45 Auto to each revolver was to etch the

new caliber with electrolysis.

The

electrolysis process involves applying 12-volts to a salt water mixture to the

metal through a mask. The

combination of the electricity and salt water etches the metal through the mask.

The mask prevents etching where it is not wanted so only the text is

etched.

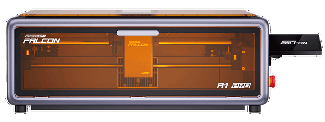

Creality Falcon A1 Pro

After doing a lot of research on the Internet the method I found was to paint

the object I want to etch, then burn off the paint with a laser etchr leaving

behind the mask to be etched into the metal.

I

purchased a

Creality Falcon A1 Pro direct from the manufacturer at an excellent Labor

Day discount price. Based on what I

read, this Chinese-built laser was the easiest to use and learn.

I also purchased the 2-watt IR laser module for marking metal, and the

honeycomb mat for cutting material.

I got a discount for purchasing all the items as a set.

This is the tool Iíll use to create the mask.

Please note that a diode or IR laser will not actually etch the metal; it only

marks the metal. However, I can

create the mask using the laser engraver, then etch the metal with electrolysis.

Falcon Design Space

Creality has a software program called

Falcon Design Space which can be downloaded from their web site for free.

One of the major benefits of the Falcon A1 Pro is that it comes with an

overhead camera. Using that camera,

I can take a photo of my work piece, then place my artwork on the exact location

I want to etch or cut.

Creality also has a

Falcon A1 Pro Parameter Guide that gives speed and laser percent power for

various types of materials using the 20-Watt and 2-Watt lasers for engraving and

cutting. With some practice and

experimentation, I modified some of the suggested settings to fit my needs.

Practicing

My

wife purchased a stainless-steel knife at the dollar store.

This is my sacrificial test knife.

I

tried engraving directly onto the knife with the 2-watt IR laser, and although

it etchd the steel, it wasnít deep enough as you can see from the above photo.

If all I wanted to do was mark the steel I could purchase a laser marking

spray which, when lased, leaves a nice permanent mark.

I

still like the adhesive mask method, but I canít cut vinyl with the laser

because when burned, the poly-vinyl chloride (PVC) produces harmful fumes.

Even though the fumes are exhausted and filtered, I donít want to take

any chances.

One

suggestion from the Internet was to use

polyester high temperature masking tape.

I purchased a 3-roll set from Amazon.

I can burn this tape without creating any harmful fumes.

I

laid the narrowest tape onto the knife blade and engraved it with the IR laser.

The laser burned through the tape exposing bare metal.

Etching Tools

To

do the etching I needed some tools.

I purchased an

adjustable power supply and

test leads from Amazon. The

power supply has banana jacks into which I can plug the test leads.

The red lead (positive) is plugged into the positive side of the power

supply, the other end plugs into one of the alligator clips which gets attached

to the gun.

I

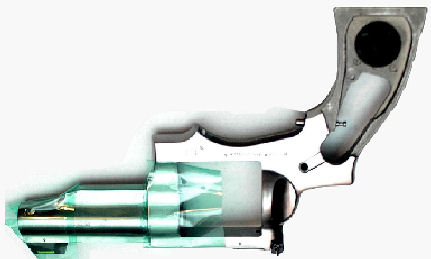

used my lathe to fabricate an etching wand out of a scrap piece of 1/2Ē brass

rod. The black lead plugs into the

negative side of the power supply, and into a hole I drilled in the wand.

The large notch up front is to hold a rubber band wrapped around a pad

which I will wet with the etching solution.

The smaller notches provide a gripping surface.

Etching the Knife

I

poured about 2 tablespoons of salt into a plastic cup and mixed it with warm

water. This is the etching

solution. I wrapped two .45 gun

cleaning patches around the top of the wand and secured it with a rubber band.

I connected the positive lead to the knife with an alligator clip and the

negative lead to the wand and set the power supply to 12-volts, 1-amp.

I dipped the pad into the etching solution, removed most of the solution

by pressing the pad against a paper towel, then touched the pad to the mask on

the knife.

When I touched the wet patch to the knife it started to turn black.

This is from the metal being removed from the knife.

I

was impressed with the results. The

engraving was clean and deep; the above photo doesnít do it justice.

I think for the gun Iíll increase the amperage to 2-amps.

The pad got very dirty so Iíll change the patches frequently for the gun.

I really like the fact that I can create the mask directly on the gun

without having to transfer it from one medium to another.

Engraving Locations

The

Redhawk has the original 45 COLT caliber marking on the barrel.

I decided to etch the new marking on the back of the ejector shroud as

shown in the above figure.

On

the Super Redhawk Alaskan there was not enough space on the ejector shroud to

also etch the additional caliber so I decided to etch the opposite side of the

barrel. This side was blank which

gave me plenty of room to etch all the calibers.

Disassembling the Revolvers

I disassembled the revolvers by removing the grips, trigger group and cylinder

so it would lay flat in the engraver.

I cleaned the surface of the gun with alcohol to remove any oil.

I

placed a strip of the wide polyester tape onto the gun so it covered the barrel

and shroud. I made sure the tape

was perfectly flat against the metal.

I covered as much of the exposed metal as I could so it wouldnít get

stained by the etching fluid. I

laid the gun in the laser cabinet upside down and took a photo with the built-in

camera. I had to lay the gun upside

down because the laser head kept running into the recoil shield of the gun and

moving it. I positioned the

upside-down text onto the ejector shroud.

I used the 2-watt IR laser to burn the letters into the tape mask.

I

etched the metal on the gun like I did the knife.

I replaced the patches frequently.

I

was pleased with the results. The

engraving came out nice and it was deep.

I

setup the green polyester hi temp tape on the blank side of the barrel as before

and put two strips of blue masking tape on the top and bottom so it would show

up better in the laser engraver camera.

I positioned the text on the barrel as shown in the above photo.

As

you can see in the above photo the engraving came out sharp and clear.

I am very pleased with this process and if I change the caliber of

another gun I can etch the barrel.

|