Converting a KRH .45 LC Redhawk to shoot .45LC and .45ACP

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers. All tools were

purchased from Brownells

unless otherwise indicated.

Introduction

I read an article in the June, 2016 issue of American

Rifleman on Ruger’s .45 Colt/.45 ACP Redhawk.

I am a big fan of interchangeable caliber guns because this

adds flexibility to the firearm, and they’re just plain fun

to shoot. I fitted .45 ACP cylinders to my two old-model

.45 Colt Ruger Vaqueros (refer to my article

Fitting a .45 ACP Conversion Cylinder), and I have

two Ruger Super Single Six Convertible revolvers that shoot

.22 short/long/long rifle out of one cylinder, and .22 WMR

out of a second cylinder. I wanted the flexibility of being

able to shoot two different calibers with the Redhawk, but I

didn’t want to pay the $800 - $1,000 for a new one. And

besides, being an amateur gunsmith I knew I could convert a

standard .45 Colt Redhawk to also shoot .45 ACP.

I found a

used older-model KRH-45-4 Redhawk on

Gunbroker for a very reasonable price. The total plus

shipping and transfer cost through my FFL dealer came to

$660, and the seller took a credit card without any

additional fees; a savings of $19.00! The best price I

could find for a new model 5032 convertible Redhawk was in

the neighborhood of $990 including shipping and transfer

fees.

Full Moon

Clips

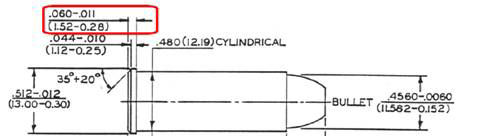

.45 Colt (or .45 Long Colt or .45 LC) cartridges headspace

on the rim. On the Redhawk the rim sets on the rear face of

the cylinder and ejector star. .45 ACP cartridges headspace

on the case mouth. Since there is no lip in the .45 LC

chamber for the mouth of a .45 ACP cartridge, that cartridge

would fall through. The way to get around this is to use a

full moon clip to hold the .45 ACP cartridges.

.45 ACP

cartridges snap into the full moon clip at the ejector

groove. With the moon clip in place .45 ACP cartridges

headspace on the rim just like a .45 LC cartridge. I

purchased a package of 8 full moon clips from MidwayUSA

product

#323361.

To get

the moon clip to work with the .45 LC Redhawk I needed to

remove metal from the ejector star. This is standard

practice for competition shooters who want to modify their

revolver to take full moon clips because this makes loading

and unloading much faster. There is an excellent video on

You Tube by

TK Custom on how they mill a Smith & Wesson 686 cylinder

and ejector star to accommodate full moon clips. The

ejector star on the Redhawk was wide enough to accommodate

the full moon clips so I didn’t have to remove any metal

from the cylinder itself.

Tools and

Parts

To work on my new Redhawk I needed some additional parts. I

purchased everything from

MidwayUSA.com unless otherwise noted.

Wolff

Hammer Spring Pack Ruger Redhawk Reduced Power

#139298 – This spring pack contains three reduced power

hammer/trigger return springs; 12#, 13#, and 14#. The

factory spring is 17#. Installing a reduced power spring

will reduce the double-action and single-action trigger

pull. On the Redhawk, the mainspring serves as both the

hammer spring and trigger return spring. This is the reason

why the single-action trigger pull is so heavy.

HIVIZ

Front Sight Ruger Redhawk 4" Barrel with Pinned Front Sight

Steel Fiber Optic

#211617 – The front sight on this older model is pinned

in place and I prefer green instead of red. HIVIZ makes

replacement front sights for both the older and new Redhawk

models, all are available from MidwayUSA.

Disassembly

There are many books and You Tube videos on how to

disassemble the Redhawk. This gun did not come with the

manual, but a quick call to

Ruger customer service and the

nice lady there sent me one. Disassembly instructions are

included in the manual. I placed all small parts in plastic

trays so they wouldn’t get lost. There are five different

plungers and springs used in the revolver and they are all

different, so I was careful not to get them confused. When

I reassembled the gun I made sure all moving parts were

properly lubricated.

Ok so

this used gun didn’t come with the special tool for

removing the monogrip. During my call to

Ruger customer service

I asked for the tool and

they sent me the tool and instructions free of charge, but

I found a video on

You Tube showing how to remove the monogrip without the

special tools.

-

Insert two plastic cards between the bottom rear of the

grip and the frame. Do this on both sides of the

frame. I used some old NRA membership cards.

-

Slip

a screwdriver blade between the two cards to spread the

monogrip away from the grip panel locator. I used

Popsicle sticks. The plastic cards help to prevent

marring the frame.

-

Slip

the bottom of the grip forward, remove the plastic cards

and separator (screwdriver blades or Popsicle sticks),

then slide the grip down off of the frame.

Inspection

After disassembling the Redhawk I performed a full

inspection. This gun was used and not cleaned very well.

If I was a professional gunsmith I would charge $40 every

time someone brought me a dirty gun! I gave it a thorough

cleaning but did not lubricate anything until after I

inspected and modified parts.

Every

big-bore Ruger single-action revolver I have ever

owned had the same two well-known problems; the chamber

throats in the cylinder were undersize, and there was a

constriction in the barrel where it screwed into the frame.

This is extremely detrimental to accuracy since the bullet

is being swaged to a diameter less than the bore diameter.

I have written a complete article on how to accurize these

Ruger big-bore single-action revolvers (refer to my article

Accurizing the Ruger Single-Action Revolver) by

opening up the chamber throats and removing the barrel

constriction.

I needed

to see if this Redhawk had the same issues as its

single-action brethren. I measured the chamber throats in

the Redhawk and they all measured 0.451”. I oiled the bore

and drove a soft lead slug from muzzle to forcing cone and

found there was no constriction inside the barrel.

Light

Primer Strikes

The Ruger web site showed that my Redhawk was built in

2008. As late as 2011 it was reported that many Redhawks

suffered from light primer strikes. Internet research

indicated this was caused by a short firing pin, thick

hammer surface, a short and/or radiused transfer bar, or a

combination of any or all three. However, not every model

or individual revolver displayed this problem. The most

common fix was to remove a small amount of metal, 0.0005 –

0.001 from the top face of the hammer so it would move the

transfer bar farther against the firing pin.

I pressed

the trigger and lowered the hammer so it would press against

the transfer bar and firing pin. I measured the firing pin

protrusion with my homemade firing pin protrusion gauge and

it measured 0.050”. With the hammer removed I pressed the

trigger and pressed the transfer bar against the firing

pin. I again measured firing pin protrusion and it also

measured 0.050”; industry standard is 0.050” – 0.055”.

Because protrusion was the same with and without the hammer

I didn’t have to remove metal from the top of the hammer

face.

Polishing

Internal Surfaces

Dry-firing the gun showed me some areas that required some

light stoning. There was a burr on each side of the trigger

guard cutout where the trigger sets. These burrs were

rubbing against the trigger creating a visible mark on the

trigger. This rubbing causes friction which increases

trigger pull.

I removed

all parts from the trigger guard and used a 320-grit flat

polishing stick to gently polish off the burrs and smooth

the surfaces. This prevents the trigger from rubbing.

I

performed the same polishing to the inside of the frame

where the hammer rides to again eliminate some burrs. You

can clearly see the scratch on the left side of the hammer

caused by a burr on the frame.

Replacing

the Mainspring

As

mentioned before, the Wolff Redhawk spring pack came with 3

lighter mainsprings; 12#, 13#, and 14#. The factory

mainspring is 17#. I was astonished at just how heavy the

single-action trigger pull was with this gun. I placed the

rear of the hammer strut in a padded vise, pushed down on

the mainspring lever, removed the takedown pin, and gently

relaxed pressure on the factory spring. I wore safety

glasses and covered the assembly with a cloth so I wouldn’t

lose the spring. I polished the hammer strut with 800-grit

wet/dry sand paper, then replaced the mainspring with the

12# replacement mainspring, the lightest of the three.

I

reassembled the gun and tested the new spring with 6 empty

.45 LC cases primed with CCI 300 large pistol primers. CCI

primers are the hardest in the industry so if the gun can

reliably ignite CCI primers, it will pretty much fire

anything else. I loaded the cases into the cylinder and

tested by cycling the gun double-action. The hammer does

not come as far back in the double-action cycle as it does

manually cocking it single-action. All 6 primers ignited,

and the trigger returned without binding.

The

double-action was already smooth, but heavy. Replacing the

factory mainspring with a lighter after-market spring

significantly reduced the trigger pull. This gun now feels

like a Smith & Wesson revolver.

Milling

the Ejector Star

The whole purpose of this exercise was to see if I could

modify the .45 LC Redhawk to take .45 ACP using full moon

clips. In order to accommodate the moon clips I had to mill

the ejector star. This was not a problem with my CNC mill,

but I needed to do a little math first.

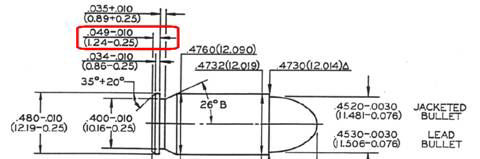

According

to

SAAMI cartridge specifications the rim of a .45 LC case

is 0.060” thick, but the rim of a .45 ACP case is only

0.049” thick. The thickness of my .45 ACP moon clips is

0.032” so it’s time to do a little math.

0.032

– moon clip

+ 0.049

– .45 ACP rim

0.081

- 0.060 – .45 LC rim

0.021 – amount to mill off of the ejector star

The

thickness of the ejector star was 0.070”. I was afraid I

would have to mill 0.032” off of the ejector star which was

almost half of the thickness. I was concerned that removing

that much metal would weaken the ejector star, but removing

only 0.021” should not affect the strength of the star.

However, I won’t be able to use moon clips for .45 LC

cartridges, but that’s really not a problem. If necessary,

I could use speed loaders.

I fixed

the cylinder to the milling table of my hobby CNC mill and

centered a 1/4” square end bit to the center of the

cylinder. I milled 0.021” off of the ejector star. I left

the ejector star installed on the cylinder; the cylinder

provided extra support during the milling process.

Now .45

LC cartridges can still be loaded one at a time as before,

or by using a speed loader. The rim of the case sets on the

outside edge of the cylinder and doesn’t touch the ejector

star. Headspace is still on the rear face of the cylinder

exactly the same as when the revolver came from the factory.

With the

recessed ejector star, I can now load six .45 ACP cartridges

with a full moon clip. I did notice, however, that a raised

primer had a tendency to bind the cylinder because the

primer would rub against the recoil shield. If I plan to

shoot .45 ACP with this revolver I need to make sure all

primers are flush or below the level of the case head.

Summary

This used revolver had been fired, but not cleaned very

well, and apparently never been disassembled. I completely

disassembled, cleaned, and lubricated it like I do to all my

guns. Milling the ejector star to accept .45 ACP cartridges

in moon clips makes this revolver much more flexible. I

can’t wait to try it out. For future owners of this gun I

will add a note to the manual indicating that this gun will

now take .45 ACP cartridges if used with a full moon clip

that is 0.032” thick. So it's not exactly a model 5032

because it doesn't have the removable front sight, but it

will shoot .45 ACP with full moon clips.

By the

way, the ejector star is a restricted part that must be

installed at the Ruger factory. If I had screwed it up I

would have had to send the entire gun to Ruger and pay for

shipping, the part, and labor.

Special

Thanks

A special thanks to the great folks at

Kittery Trading Post in Kittery, Maine. Their customer

service has to be second to none; they helped to make this

purchase and the transfer process quick, easy, and

affordable. Check out

their web site for great prices on used guns.

|