Adding a Flash Suppressor to a Ruger Mini-30

or "How I Became Intimate with a 10-Inch Mill Bastard File"

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

A

long time ago, I purchased a Colt AR-15 Sporter in 7.62 x 39

caliber, the same caliber as the AK-47.

Since the lower was the same as a .223 AR-15, I

purchased a .223 Remington upper, which functioned

perfectly. I now

had an interchangeable caliber AR-15.

Although I purchased 1,000 rounds of Wolf 7.62 x 39,

I never really fired it.

I sold the Sporter to a friend, and with the money, I

purchased an AR-15 lower for my .223 Remington upper, and a

Ruger Mini-30.

The

Ruger Mini-30 is chambered for the 7.62 x 39 cartridge; it

was Ruger’s answer to all the AKs and SKSs being imported.

I wanted a rifle to shoot the 7.62 x 39, but the

AK-47 was too expensive, and I never really liked the SKS.

I’ve owned Ruger Mini-14s before and liked that

pattern of rifle, so I decided on the Mini-30.

I’ve

never really liked the large front sight on the Ruger

Mini’s. I prefer

a military-type front sight with the protective wings.

Choate Machine and Tool, Inc. makes a combination front

sight and flash suppressor for the Mini-14.

I was hoping this would also fit the Mini-30, but man

was I wrong! The inside diameter of the front sight was

0.54”, and although the barrel on the Mini-30 was tapered,

at the widest point where the new sight would go, the barrel

measured 0.62”. That

meant I would have to remove at least 80 thousands of an inch

around the barrel. The

preferred method would have been to remove the barrel and turn

it down on a lathe. Well,

I don’t have a lathe, so the next method was to draw-file

the barrel. Draw-filing

over 80 thousands is not for the faint of heart.

But even if I messed it up, I was going to install a

red-dot sight anyway so I really wouldn’t need the front

sight; but the flash hider would be nice. There are

professional gunsmiths who are probably cringing right now,

but hey, I'm a kitchen-table gunsmith. I’ve

never really liked the large front sight on the Ruger

Mini’s. I prefer

a military-type front sight with the protective wings.

Choate Machine and Tool, Inc. makes a combination front

sight and flash suppressor for the Mini-14.

I was hoping this would also fit the Mini-30, but man

was I wrong! The inside diameter of the front sight was

0.54”, and although the barrel on the Mini-30 was tapered,

at the widest point where the new sight would go, the barrel

measured 0.62”. That

meant I would have to remove at least 80 thousands of an inch

around the barrel. The

preferred method would have been to remove the barrel and turn

it down on a lathe. Well,

I don’t have a lathe, so the next method was to draw-file

the barrel. Draw-filing

over 80 thousands is not for the faint of heart.

But even if I messed it up, I was going to install a

red-dot sight anyway so I really wouldn’t need the front

sight; but the flash hider would be nice. There are

professional gunsmiths who are probably cringing right now,

but hey, I'm a kitchen-table gunsmith.

The

front sight had a lip on the inside that would rest up against

the muzzle. I

measured the depth of the lip then marked the barrel back from

the muzzle the same amount.

I installed a stop-collar at the mark to prevent

marring the barrel beyond that point.

The stop-collar was a bit large so I had to wrap some

tape around the barrel first before installing the collar.

I

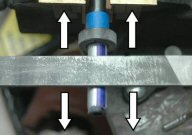

disassembled the rifle and put the barreled action in my bench

vise. I marked the

area to be filed with a blue marker, chalked a 10-inch mill

bastard file, and began draw-filing as shown in the photo.

Note the stop-collar.

After I removed the blue with the file, I rotated the

barrel, re-marked the area, and continued to draw-file.

I repeated the rotate/mark/file process and constantly

tried the new sight for fit. I

disassembled the rifle and put the barreled action in my bench

vise. I marked the

area to be filed with a blue marker, chalked a 10-inch mill

bastard file, and began draw-filing as shown in the photo.

Note the stop-collar.

After I removed the blue with the file, I rotated the

barrel, re-marked the area, and continued to draw-file.

I repeated the rotate/mark/file process and constantly

tried the new sight for fit.

Because

the barrel was tapered, eventually the new sight would fit at

the muzzle end of the barrel, but not further up.

At this point I began to draw-file only the upper part

of the barrel close to the stop-collar until the sight would

fit farther up the barrel.

When the sight would fit onto the barrel with only the

width of the file left, I switched to a narrow safe-edge Swiss

pattern file so I could draw-file a narrower length.

Eventually I couldn’t draw-file anymore, so I used

the Swiss file and filed perpendicular to the barrel and up

against the stop collar to reduce the diameter of the final

part of the barrel. In

the left photo, you can clearly see the lip where the

stop-collar was positioned, and the roll-pin notch from the

original sight. The

smooth area in front of the lip was where I filed

perpendicular to the barrel. Because

the barrel was tapered, eventually the new sight would fit at

the muzzle end of the barrel, but not further up.

At this point I began to draw-file only the upper part

of the barrel close to the stop-collar until the sight would

fit farther up the barrel.

When the sight would fit onto the barrel with only the

width of the file left, I switched to a narrow safe-edge Swiss

pattern file so I could draw-file a narrower length.

Eventually I couldn’t draw-file anymore, so I used

the Swiss file and filed perpendicular to the barrel and up

against the stop collar to reduce the diameter of the final

part of the barrel. In

the left photo, you can clearly see the lip where the

stop-collar was positioned, and the roll-pin notch from the

original sight. The

smooth area in front of the lip was where I filed

perpendicular to the barrel.

I

degreased the filed area with Acetone, cold-blued using

Van’s Instant Gun Blue, then coated with gun oil.

I used a soft-faced mallet to drive the sight in place,

then rotated it until it was in the proper position.

I took a 5/32” drill bit and drilled a detent in the

barrel for the sight’s setscrew, then installed the setscrew

using Loctite blue.

I

didn’t want to use the 1/8” roll pins that came with the

sight because I thought a 1/8” hole might make the barrel

too thin, so I decided to use 3/32” roll pins instead.

I used a #42 0.093” drill bit and carefully drilled

holes in the indicated positions through the sight and bottom

of the barrel. I

then installed two 3/32” roll pins that I cut to the proper

length.

This

photo shows the results. The

end of the sight comes right up to the lip, and the setscrew

(you can just see on the bottom) and roll pins keep the sight

in place. This

project took hours to complete because of the draw-filing, but

I’m very pleased with the results, and no special tools

other than normal hand/power tools were required to complete

the project. This

photo shows the results. The

end of the sight comes right up to the lip, and the setscrew

(you can just see on the bottom) and roll pins keep the sight

in place. This

project took hours to complete because of the draw-filing, but

I’m very pleased with the results, and no special tools

other than normal hand/power tools were required to complete

the project.

Addendum

4/18/2009

After adding M1 carbine sights to this rifle (refer to my

article Installing

a M1 Carbine Rear Sight on a Ruger® Mini Thirty®) I

finally took it out to the range.

I had a feeling it would shoot high because the post on

the new front sight was lower than the original.

Sure enough, even with the rear sight at its lowest

position, the rifle shot about six inches high at 100 yards.

There

are two ways to make a firearm shoot lower; either lower the

rear sight, or raise the front sight.

Since the rear sight was already as low as it would go,

I decided to install an adjustable front sight post similar to

an AR15.

First

I used my hobby CNC mill to create a front sight post from

10-24 threaded rod. I

milled a flat onto the threaded base of the post so a set

screw would prevent it from turning under recoil.

I then cold-blued the sight post.

I

removed the flash suppressor from the barrel and milled off

the sight post. This

suppressor has been heat-treated so it’s very hard.

To avoid breaking taps I used oversized drill bits.

For the 10-24 sight post I should have used a #25 drill

bit, but instead I used a #19, slightly larger, bit.

I first used a 1/8" square end bit to plunge-mill a pilot

hole in the top of the

front sight between the protective wings,

then used the #19 bit to drill out the hole.

I then used a 10-24 tap to tap the threads.

For

the 8-32 set screw I should have used a #29 drill bit, but I

used a larger #24 bit to drill the set screw hole in the side

of the sight. I

then tapped it for 8-32.

I

measured the original sight and found the post was 1.125”

above the center line of the bore.

I installed the threaded post into the top hole leaving

the top of the post 1.125” above the center line of the

bore. This made

the post slightly higher than the protective wings.

I installed the set screw with blue Loctite to hold the

post in place. I

then reinstalled the flash suppressor onto the barrel.

I now have an adjustable front sight post to get my

rifle accurately sighted in.

|