Building

a Folding Gun Cart

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Introduction

As mentioned in my article Installing

a Half-Cock Hammer in an Old Model Ruger® Vaquero® I am getting back into Cowboy

Action Shooting™. One

of the additional items I needed was a gun cart.

The gun cart is used to move long arms, ammo, and other

gear from stage to stage during a match.

I currently have two gun carts; an ugly one I quickly

assembled out of plywood, and a really cool one in the shape

of an outhouse that I won in a shooting match.

I built the plywood cart when I first started shooting

cowboy matches just so I could have something to use.

The outhouse cart I won was very heavy and required two

people to load into and out of my Ford Explorer.

I replaced the Explorer with a little Jeep Wrangler

which doesn’t have enough room in the “tub” for the

outhouse gun cart so I decided to build a new, folding gun

cart.

Requirements

There are as many different designs of gun carts as there are

different cowboy shooters.

The gun cart often matches the character of the shooter

and can be as personal as the shooter’s alias and costume.

Gun carts can range from simple units made from scraps of

whatever you may have laying around to elaborate contraptions

that not only fulfill the needed purpose but are almost an art

form in their own right. I’ve

seen simple frames made of wood and/or PVC pipe, modified golf

carts, and very elaborate buckboards, covered wagons and stage

coaches. Because

of space, weight, and budgetary considerations, my new gun

cart had to meet the following requirements:

- Fold

up flat for easy storage and transportation

- Light

weight to easily lift into and out of the Jeep

- Fit

into a 36”-wide horizontal space when folded - this is

the distance between the wheel wells in the tub of my Jeep

- Carry

4 long arms and a range bag/box when unfolded - I only use

one rifle and one shotgun at a time, but sometimes I have

a friend come along so it’s good to be able to carry two

extra long arms. Or

if there is a long-range side match I have a .45-70 rifle

I may want to bring along.

Also, under SASS rules, firearms must be

transported safely so their muzzles never sweep

contestants or bystanders.

Typically this means long guns, i.e. rifles and

shotguns are transported with their actions open and

muzzles pointed up.

- Be

at least 40-inches high when unfolded - this will make it

easy to move around. My

arms are 40” above the ground with my forearms extended

at right-angles from my body and parallel to the ground.

Construction

I’m no Norm Abrams and my woodworking tools and skills are

rudimentary at best. I

already had all the power and hand tools I needed for this

project so I didn’t need to purchase any additional tools.

If you are

an advanced woodworker you may find the photos and

descriptions very elementary; you can probably work just from

the plans. If you

are an amateur like me, hopefully you will find this article

helpful. You will

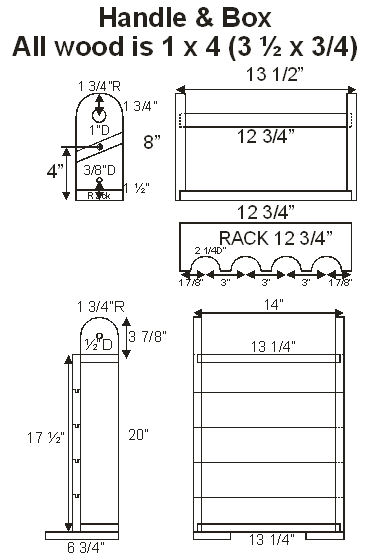

find full-size plans and a materials list at the end of this

article.

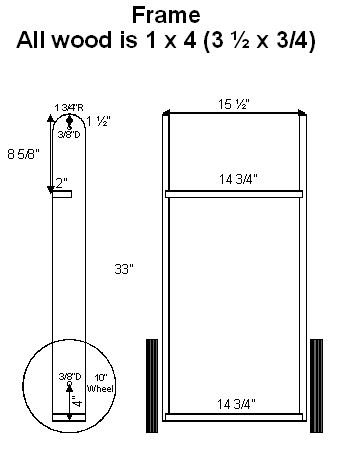

Before we

get started you need to know that not all 1” x 4” wood is

the same. First of

all I purchased “select” pine because it was clear and had

no knots. Also,

most of the boards I selected were straight.

If you’ve ever tried to find 8-foot boards that

weren’t bent or bowed, you know what I mean.

I purchased

from both Lowes and Home Depot since I have both of those

home-improvement stores close to my home.

1” x 4” actually measures 3/4“ x 3 1/2“.

It turned out that the wood I purchased from Lowes

measured 13/16” thick so the cross pieces for my rabbets

were thicker than the rabbet joint by 1/16”!

The wood from Home Depot measured exactly 3/4“ x 3

1/2“ so I should have used only Home Depot wood.

Unfortunately, Lowes was on the way home from somewhere

so I stopped there to buy my wood.

I should have measured first and checked both stores

before buying. The

advantage of the thicker wood is that all of my dado joints

were very tight which means my box and frame are very sturdy.

Lesson learned!!!

Cutting

the Pieces

I used my

compound miter saw to cut all the pieces I needed from three

1”x4”x8’ select pine boards.

You can also use a miter box and miter saw to cut the

pieces, but you want to make sure the cuts are square and of

the same length. My

miter saw has a stop block I can adjust so when cutting

multiple pieces of the same size I only had to measure the

first one, then used the stop block to ensure all the other

pieces were cut identically.

I cut the following pieces:

2

@ 33” – frame sides

2

@ 20” – box sides

2

@ 14 3/4“, one ripped to 2” wide – frame supports

5

@ 14” – box bottom

2

@ 13 1/4“ – box supports

1

@ 12 3/4” – handle support

2

@ 12 3/4” – shelf

2

@ 8” – handle sides

2

@ 6 3/4“ – front legs

I ripped

one of the 14 3/4“ boards to 2” wide; this was the top

support piece for the frame.

It had to be narrower in width so the guns wouldn’t

it the front edge when setting in the rack cutouts.

I also cut a 12 3/4” length from the 1” dowel which

became the hand bar. Refer

to the plans and materials list at the end of this article.

Routing

the Rabbets and Dados

I wanted

the frame, handle, and box to be sturdy so I used rabbet and

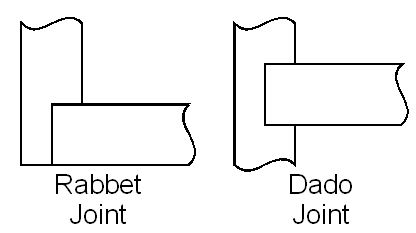

dado joints to hold the cross pieces in place.

A rabbet is a channel cut into the end of a piece of

wood, a dado is a channel cut into the middle of a piece of

wood; each is designed to hold a cross piece.

Since the

wood was 3/4“ thick I used a 3/4“ square router bit to cut

the rabbets in the ends, and dados at the proper locations of

the frame, handle, and box sides.

Each rabbet and dado cut was 3/8” deep; half the

thickness of the wood.

The

distance from the center of the router bit to the outer edge

of my router base is 3-inches.

For each rabbet cut I drew a line with a pencil 3

3/8” up from where I wanted to cut and placed a piece of

scrap wood against that line.

3” up from the end of the wood would be the center of

the 3/4“ bit so I had to move the line 3/8” farther up so

the edge of the bit would be even with the bottom edge of the

wood. I squared

the scrap wood with a T-square and clamped it place with C

clamps. This piece

of wood acted as a straight edge to guide the router.

Note:

I always mark wood with a pencil and make light marks.

These marks are easy to remove by sanding.

Ink pens and felt-tip markers seep into the fibers of

the wood and are difficult to remove.

For each

dado cut I only had to mark 3” up from the location of the

dado because the plans show the center of the dado rather than

the edge.

Next I used

a 1” wood bore to cut the holes for the round hand bar.

I cut each hole 3/8” deep.

Routing

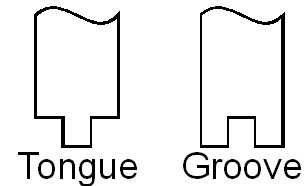

the Tongue and Groove Joints

The bottom

of the box is made up of 5 pieces, each piece is 3 1/2“ x

14”, but held together with tongue and groove joints.

I didn’t want to spend the $80+ dollars for a tongue

and groove router bit set, so I cut my own.

I attached my router to my router table and set the

depth of the 3/4“ bit to cut a 1/4“ x 1/4“ groove.

I cut this groove on both sides of the edge of a board

leaving a 1/4“ tongue in the middle of the edge.

I replaced

the 3/4“ bit with a 1/4“ square end bit and adjusted my

router table to cut a 1/4“ x 1/4“ groove down the middle

of one edge of a board. This

cut the groove which mated with the tongue of the opposite

board. One

end-board had one tongue and one plain edge, the other

end-board had one grooved and one plain edge.

The plain edge is the outside edge of the bottom of the

box.

Drilling

the Holes

I wanted to make sure all holes were straight so I used a

drill press to drill the holes.

I drilled 3/8” holes in the handle and frame for the

carriage bolts that would hold the handle in place, and 1/2“

holes in the frame and box for the wheels hex-head bolts that

would hold the wheels and box in place.

I marked

the locations for all the wallboard screws 3/8” in from the

edge of the wood and drilled all the holes using a 3/32”

drill bit. I

countersunk each hole using a countersink bit so the screw

heads would set flush with the surface of the wood.

I did not drill the matching holes in joining pieces of

wood until final assembly.

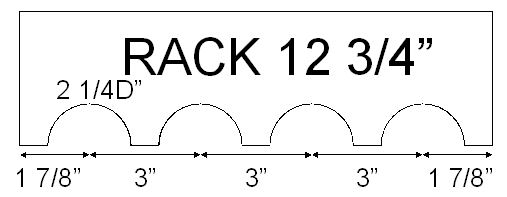

I used a 2

1/4“ hole saw to cut four half-holes in the rack.

These are used to support the guns.

Finishing

the Wood

I used a 3

1/2“ circle as a template and traced around the tops of the

frame and handle sides since I wanted to radius them.

I used an 80-grit sanding belt and my belt sander to

sand the radius. I

chucked the sander upside down in my bench vise and sanded the

radius by hand.

I used a

1/4“ rounding over router bit to round all the sharp edges

of the wood. I

then sanded each piece of wood using 120-grit sand paper.

For the boards I used my belt sander and a 120-grit

sanding belt.

I stained

each piece of wood with Minwax®

#231 Gunstock, then finished with Minwax®

Fast Drying Clear Satin Polyurethane.

I applied two coats of polyurethane and sanded with

400-grit sand paper between coats.

Assembly

I used a

corner clamp to assemble the frame, handle, and box.

The rabbets, dados, and corner clamp ensured each

assembly was square. Once

each piece of wood was in place I used a 3/32” drill bit to

finish drilling the holes and assembled with #6 x 1 1/4“

coarse black wall board screws.

I live in the south and southern pine is so soft that

regular wood screws strip out of their holes very easily so I

use wall board screws instead.

I decided not to glue the joints in place in case I had

to disassemble the cart to make modifications, which I did as

you will see later.

I put two

3/8” washers between the frame and handle to act as spacers

to keep the handle centered.

I used a 3/8” fender washer and a nut to secure the

3/8” carriage bolt which holds the handle to the frame.

Since I didn’t want to over-tighten the nuts I used

Loctite® blue on the threads to secure the nuts in place.

I used

three 1/2“ flat washers as spacers to keep each wheel away

from the frame, and an additional 1/2“ washer between the

box and frame to also act as a spacer.

I used a 1/2“ fender washer and two 1/2“ nuts to

secure the 1/2“ hex-head bolt that holds each wheel and box

to the frame. I

used two 1/2“ nuts and tightened them together very tight in

a “jam nut” configuration so they wouldn’t back out.

I cut a

strip of red felt 3/4” x 20” and used contact cement to

glue it to the front of the rack.

The felt will protect the finish of the guns.

When the

handle is in the unfolded position it is rotated about

10-degrees to the rear. This

allows the rack to be positioned a little bit forward, and the

round hand bar to be positioned a little bit to the rear so

the guns don’t interfere with my hands when moving the cart.

I rotated the handle to the proper position and drilled

a 1/4“ hole through each side of the frame and handle to

prevent the handle from rotating.

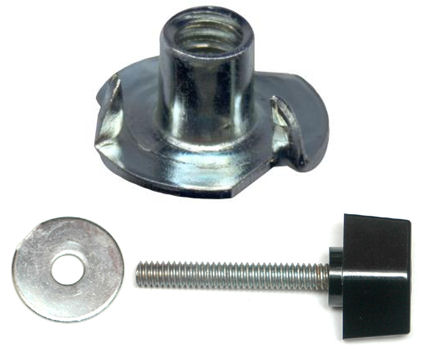

I installed a 1/4-20 T-nut through the hole on the

inside of the handle. I

purchased a 12” piece of 1/4-20 threaded rod and cut two 2

1/2“sections. I

used some Loctite® red (the permanent stuff) to glue a

plastic 1/4-20 T-knob onto one end of the threaded rod.

With the handle rotated up in place I insert the

threaded rods through the holes in the frame and handle and

screw them to the T-nuts to hold the handle in place during

use.

I also

drilled a 1/4“ hole through each side of the box and frame

with the box folded into the frame.

I insert the threaded rods through these holes to keep

the box folded in place during transport in my Jeep.

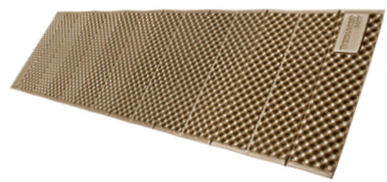

My wife

found a Therm-A-Rest® Z Lite™ pad for about $0.99 at our

local Goodwill outlet. They

normally retail for about $40!

I cut a piece out of this pad and glued it to the

bottom of the box to rest the butts of the long arms.

This pad is soft so it won’t mar the finish on the

guns, and the egg-crate pattern prevents the guns from moving.

To finish

my gun cart I purchased a Flambeau Dry Box at Walmart which

comes with a storage compartment in the lid and a removable

tray. I will use

the lid to store small items like ear plugs and cleaning

supplies, the removable tray I’ll use to store my timer,

shooting glasses, tools, and other gear, and the box itself

will hold ammo, and other larger items.

Modifications

After the cart was assembled everything worked as it should.

It folded into a neat package that fit into my Jeep,

and was lightweight and easy to carry.

I did have to make a few modifications to improve the

overall function.

Modification

#1: Double-Barrel

Shotgun – The shotgun breaks open at such an acute angle

that the top of the barrel was hitting the 2” cross brace on

the frame. I cut a

2 1/4“ half-hole notch out of the cross brace, stained and

finished it with polyurethane, and covered it with red felt

like the rest of the rack.

Now the shotgun sets securely in its own rack, which it

didn’t before. The

yellow bungee cord you see in the above photo holds the guns

in place while moving over rough ground.

Modification

#2: Dry Box –

The dry box fit very tightly in the box which would eventually

cause the finish to wear and possibly the wood to bow out.

I used my router and 3/4“ router bit to relieve

1/8” from the inside of each box rail just where the dry-box

set. I stained and

finished each relief cut as before; now the dry-box doesn’t

touch the sides of the bottom of the gun cart.

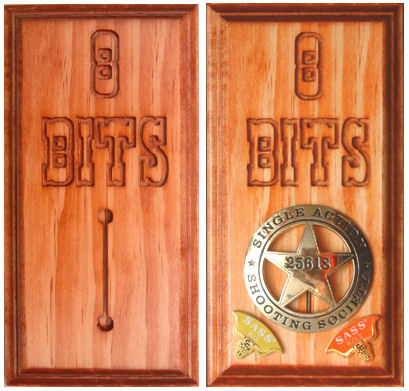

Modification

#3: Personalized

Plaque – I wanted to personalize my gun cart by mounting a

plaque with my alias and SASS badges.

I cut a piece of wood 7” long and used my router

table and a 1/2“ cove and bead bit to put a nice edge on it.

Then I used

CorelDRAW®, my CAD/CAM

software BobCAD-CAM v20

and my MAXNC

10 CL CNC hobby mill to engrave my alias and a notch for

my membership badge. I

stained and finished the plaque to match the rest of the gun

cart.

I used

clear silicon RTV to mount my badge and Range Officer (RO) I

and II pins onto the plaque.

I mounted the plaque on one of the frame uprights by

drilling and countersinking holes on the inside

of the frame. That

way screw heads wouldn’t show on the plaque.

The RO I

and II pins came with two pins on the back for attaching to

clothing. I

pressed each pin into the wood at the proper location; this

left two marks from the rear pins.

I used a small drill bit to drill where the pins left

marks. This

allowed the pins to set into those holes to keep them in

place. I again

used clear RTV on the backs of the pins to hold them in place.

Modification

#4: Reduce Angle

of Frame – After I put everything together I discovered that

the frame leaned back too far.

The weight of four guns would cause the cart to tip

backwards even if the dry-box was full of ammo.

Eventually as I used ammo the dry box would get lighter

and the cart would fall backwards.

I cut a piece of wood 1/2“ x 3/4“, stained and

finished it, then mounted it on the bottom of the box.

This reduced the angle of the frame so when filled with

guns it wouldn’t have a tendency to tip over.

Modification

#5: Build a Shelf

– I didn’t want to have to bend over all the time to get

ammo out of the box to fill my loading strip so I built a

shelf into the handle on which I can set cartridge and shot

shell boxes. Because

the handle and frame both tip backwards I had to rout dado

channels into the handle sides at an angle.

I set up my

table saw miter gauge to 67 1/2 degrees and clamped on a piece

of wood as an extension. I

installed a 3/4“ square router bit 3/8” above the surface

of the table. I

clamped a piece of wood on the edge of the router table to act

as a straight edge so the center of the dado would be four

inches up from the bottom cut the angled dado.

I tried routing the dado without the straight edge

guide and all I succeeded in making was a curved dado cut,

which proved to me that I needed the guide.

I rotated

the miter gauge to 67 1/2 degrees on the other side of the

90-degree mark and cut the opposite angle on the other handle

side. I drilled

holes, counter-sunk, stained and finished each side as before.

To form the

shelf, I cut two leftover pieces of wood 12 3/4“ long,

drilled holes in one side, and used 1/4“ dowel pins and

Gorilla Glue® and clamped the two pieces together.

I scraped off the excess glue, sanded, stained, and

finished as before.

Once the

shelf was completed I assembled the handle so the shelf was 2

1/4“ back from the front edge.

This prevents the guns from hitting the front edge, and

provides a little more shelf space.

I also discovered that if I left cartridge boxes on the

shelf while moving the cart, they would slip off.

I added a 3/4“ x 3/4“ strip of wood to the rear

edge of the shelf to prevent this from happening.

Below are

photos of the completed project.

Woodworking is just as much a part of gunsmithing as is

metal working. No

only does my gun cart look nice and function as designed, it

should last me for many years.

Plans

Materials

List

|

Qty

|

Description

|

|

3

|

1”

x 4” x 8’ select pine or other wood of your choice

|

|

1

|

1“

x 24” wood dowel

|

|

2

|

3/8”

x 2” carriage bolts

|

|

4

|

3/8”

flat washer, these act as spacers between the frame and

handle

|

|

2

|

3/8”

fender washer

|

|

2

|

3/8”

nut

|

|

1

|

Loctite

blue, tube

|

|

1

|

Loctite

red, tube

|

|

2

|

10”

x 1.75” hard rubber wheels

|

|

2

|

1/2“

x 4” hex-head bolt

|

|

4

|

1/2“

nut

|

|

10

|

1/2“

flat washer, these act as spacers between the wheels and

frame, and frame and box

|

|

2

|

1/4“

T-nut

|

|

1

|

1/4“–20

x 12” threaded rod

|

|

2

|

1/4“

T-knob

|

|

2

|

1/4“

fender washer

|

|

2

|

3/4”

x 12” aluminum strip

|

|

1 box

|

6 x 1

1/4“ coarse black wall board screws.

I live in the south and southern pine is so soft

regular wood screws strip out of their holes too easily

so I use wall board screws instead.

|

|

1

|

3/4”

x 20” felt strip

|

|

1

|

Stain,

small can, color of your choice, I chose Gunstock since

I like the red color

|

|

1

|

Polyurethane,

small can, finish of your choice, I chose satin since I

didn’t want a gloss finish

|

|