Installing

a Wide Spur Blackhawk Hammer in a Bisley Frame

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

I have

always preferred a checkered, wide spur hammer on my

revolvers; especially one that I carry in the woods. The

checkered wide spur gives me greater purchase on the hammer

if my hands are cold, wet, or if I am wearing gloves. This

is especially important if the revolver is a single-action

where I have to cock the hammer every time.

Ruger

makes two styles of grip frames for their single-action

revolvers; the standard “plow share” grip, and the

Bisley grip. Each

grip comes with its own style of hammer.

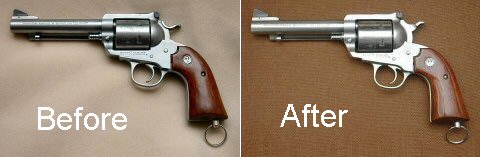

I have a stainless steel, Ruger Bisley Blackhawk with

a 5 1/2“ barrel in .45 LC that I regularly carry with me

when I hunt. The

Bisley hammer only comes with a narrow spur, so I want to

fit a wide spur standard Blackhawk hammer to my Bisley

Blackhawk. Because

of the differences in the two grip frames, a standard

Blackhawk hammer will fit in a Bisley grip frame, but a

Bisley hammer will not fit in a standard grip frame.

So fortunately, I will not have to alter the shape of

the hammer.

I purchased

a Super Blackhawk hammer assembly #780-000-535 from Brownells.

The standard Blackhawk hammer comes only with horizontal lines

cut into the wide spur. The

tops of these cuts are rounded, which does not provide much

purchase when cocking the hammer. So,

I will have to cut new checkering to make nice sharp points. Hand

checkering is very time consuming and not for the faint of

heart. I was

fortunate to have had personal tutoring on hand checkering by

the late Dave Sample, master gunsmith.

The first

step was to prepare the hammer for checkering. I

took a #0 pillar file and cut a notch in front of the spur. This

notch will provide clearance for the checkering file.

Next, I

used a blue marker to coat the spur. This

helps me to measure progress. I covered the front of the

hammer with thin leather and masking tape to prevent me from

marring the surface. I

then set the hammer in my vise about 1/4“ below the top edge

of the jaws. This

allows me to use the front edge of the bronze vise jaws as a

guide to ensure my vertical cuts are nice and straight.

Using the

edge of the bronze vice jaw as a guide, I took my 20

lines-per-inch (LPI) checkering file and began to cut the

vertical lines. The

surface of the hammer was hardened, but after I broke through

the surface, the metal cut easily. I

filed until the checkering file no longer cut metal.

I then

raised the hammer in the vise and finished cutting all of the

vertical lines. After I complete the horizontal cuts, I will

file off the partial points on the edges.

It took me three hours to complete the vertical cuts,

primarily because I could not take full strokes with the file.

I could only take short strokes on the front of the

spur.

Using the

front of the spur as a guide, I cut all of the horizontal

lines. This only

took one hour because I could take long, full strokes with the

checkering file. After

I completed the horizontal cuts, I took the #0 pillar file and

removed the partial points on the edges.

I took

strips of 400-grit wet/dry sand paper and polished out the

file marks on the top of the hammer. This

took another hour to complete.

So, this 3/4 square inch of metal took about 5 hours to

checker.

I am not

quite ready to install the hammer yet.

I now need to prepare the sear engagement surface.

I reduced the sear engagement surface to 0.014” and

polished the surface as described in my article Accurizing the Ruger Single-Action Revolver.

I

reassembled the revolver and put some Brownells Action Lube on

the hammer and sear mating surfaces.

I now have a very positive grip on the hammer spur when

I cock the hammer.

Most of the

tools I used I purchased either from Brownells

or MidwayUSA.

|