The

Case of the Double-Tapping AR10

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Introduction

One of my long-time shooting buddies, Dave, brought me an

AR10 that was built by a different friend, James, from

commercially available parts. James had purchased a bare,

serialized lower and had it transferred through his FFL

dealer. He then purchased a lower parts kit and assembled

his lower. When Dave attempted to shoot this home-built

AR10, sometimes when he pulled the trigger the rifle would

fire two rounds, not just one! After about the third time

this happened Dave stopped shooting the rifle and brought

the lower receiver to me to have a look.

Initial

Inspection

I first wanted to test the function of the disconnector.

With my finger pressing the trigger I pulled the hammer back

so it would engage the disconnector. With my thumb on the

hammer to prevent it from hitting the frame, I released the

trigger. The disconnector released the hammer and it should

have been caught by the sear, but the hammer completely fell

to the front of the receiver, which would have caused a

second round to be fired. With my finger off the trigger,

when I pulled the hammer back the sear caught the trigger.

Based on

this initial inspection, hereís what was happening:

-

Dave

pulled the trigger.

-

The

sear released the hammer which fired a shot.

-

The

bolt being driven back cocked the hammer which was

caught by the disconnector.

-

Dave

released the trigger which caused the disconnector to

release the hammer.

-

The

hammer missed the sear which caused the rifle to fire a

second time causing the double-tap.

-

When

the bolt came back the second time the hammer was caught

by the sear because Dave had let off the trigger.

I

discovered that the trigger pin was not seated fully in the

receiver. It had slipped out of the left hole and was

protruding from the right side of the receiver causing the

trigger and disconnector to be crooked. The trigger and

disconnector being crooked in the receiver prevented the

disconnector and/or sear from catching the hammer. Ok, so

what caused the trigger pin to come out of the receiver?

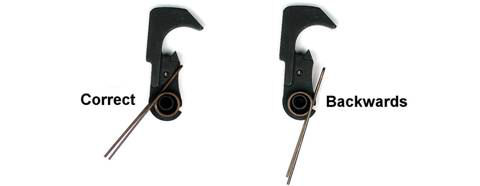

The

hammer and trigger pins are exactly the same for an AR10

(and AR15 by the way). The pin has two grooves to prevent

it from moving once seated in the receiver. When the pin is

used as the hammer pivot pin, there is a small spring in the

center of the hammer that fits in the middle groove of the

pin to prevent it from moving. When the pin is used as the

trigger/disconnector pivot pin, one leg of the hammer spring

sits in the outside groove to prevent the pin from moving.

Notice how the grooves are rounded; a tap on the pin with a

punch will unseat the pin. On Jamesí rifle I noticed that

the hammer spring leg was not setting in the groove of the

trigger pin.

I removed

the hammer, trigger and disconnector from the receiver and

compared them to a set of AR15 trigger parts I had left over

from when I replaced the trigger group on my own AR15. I

immediately noticed that the hammer spring had been

installed backwards on Jamesí rifle! This caused the leg to

be set at such an angle that it would not contact the groove

in the pin. This was also causing the spring to be flexed

backwards.

I

installed the spring correctly, reinstalled the trigger

parts and found that the trigger/disconnector pin now would

not move because the leg of the hammer spring was sitting in

the groove correctly. When manually cycling the hammer with

the trigger pulled, the hammer engaged the disconnector.

When I released the trigger the hammer was caught by the

sear indicating the parts were now working correctly.

Range

Session

I went with Dave to the range to test the rifle. I loaded

two rounds in a magazine to make sure the trigger group was

functioning correctly. After each shot, I held the trigger

back, then carefully released it to ensure the disconnector

and sear were working properly. I could both hear and feel

the disconnector release the hammer and be caught by the

sear. I then loaded 5 rounds in a magazine and the rifle

continued to function properly. Problem fixed!

Summary

Iím all for building guns from parts and often times to fix

a gun all that is needed is a replacement part. However,

when working on any gun I always have a schematic (exploded

parts view) available to help with proper orientation and

location of parts. If a schematic is not available I use a

digital camera and take photos as I disassemble the gun so I

know how to reassemble it. As for installing a part

backwards; Iíve done it many times and will probably do it

again! We learn through our mistakes. To James credit he

built his rifle from parts having never disassembled one,

and it really is a beautiful, and now correctly functioning,

rifle.

|