I have a

concealed carry permit for the state of

North Carolina

and I recently purchased a Taurus® 24/7 compact in .45 ACP.

After doing a lot of research on the Internet, I

found the Armalaser

RSS built especially for this pistol.

It is activated simply by touching the metal rear

with my trigger finger.

A frame-mounted laser provides many advantages,

especially in low light conditions, not to mention I am now

finding it difficult to focus on the front sight with my

tri-focal glasses!

One of

the problems with mounting a laser on a gun is finding a

holster that fits. Since

this will be my primary carry gun I needed a suitable

holster for it. Many

years ago I read an article in a gun magazine on how to make

your own custom leather holsters.

That year my wife bought me a leather crafting kit

from Tandy

Leather and I’ve been making my own holsters ever

since.

After

many years of trial and error, I’ve developed a holster

pattern that works well for me.

It is similar to a pancake holster with belt notches

so I can wear it outside the pants on my belt, with the

addition of two belt loops so I can wear it inside the pants

as well.

The

process for making a custom leather holster requires the

following steps:

Step

1:

Trace the outline of the gun for which I am

creating the holster.

Step

2:

Create the holster pattern around the gun

tracing, then cut out the pattern.

Step

3:

Trace the pattern onto 8-9 oz. leather, then

cut out the pieces.

Step

4:

Prepare and finish the leather.

Attach any snaps at this time.

Step

5:

Assemble the holster.

Step

6:

Wet-mold the holster to the gun.

Step

7:

Attach any additional hardware.

Step

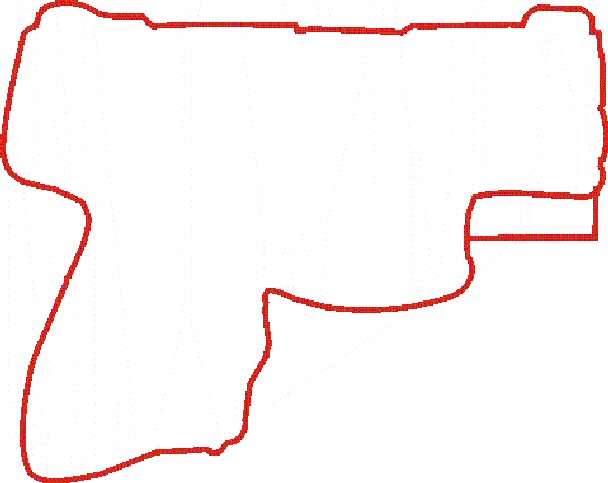

1: Trace the Gun

First

I made sure the gun was unloaded! I drew a

straight line with a felt- tipped pen and placed the top of

the gun along that line. I made sure the front sight

and center of rear sight were both on the line. Then I

rolled the gun over onto its side and used the felt-tipped

pen to trace around the entire gun.

This "rolling" of the gun accommodates any

thicknesses due to cylinders, etc. If the gun is too large to fit on a sheet of paper, I

place the grips outside of the paper.

The grips aren’t usually covered by leather.

When I

first started making holsters, I didn’t have a suitable

drawing program so I traced the gun on graph paper.

The graph paper made it easy to draw the final

pattern.

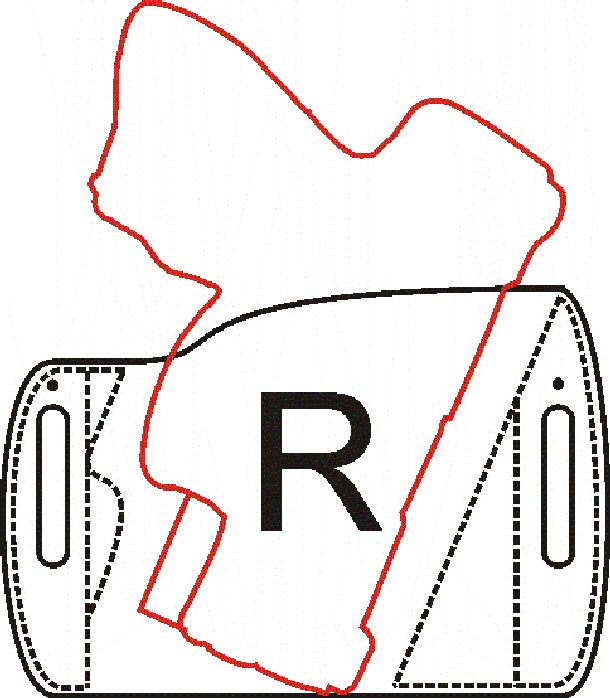

Step

2: Create and

Cut Out the Holster Pattern

I use

CorelDRAW® 12 to design all my holster

patterns. After the

gun was traced I scanned it into my PC and imported it into

CorelDRAW®. CorelDRAW®

comes with a program called CorelTRACE® which allows me to

convert the traced image into a line drawing.

Although this step isn’t necessary, it makes it

easier to manipulate the tracing.

Once the

tracing is imported and converted I designed the pattern

around it. In

the pattern above, the gun is canted forward 23-degrees.

For me, this makes it easier to draw and the bottom

of the holster doesn’t dig into my hip. Also,

this gun only comes with extended magazines, so the forward

cant helps prevent the grip from protruding behind me.

In other words, the grip sits against my body.

I usually use red for the gun and black for the

holster to help distinguish between the two.

Typically,

a pancake holster is made of two identical halves that are

stitched together. The

dotted lines in the pattern above show where the holster

will be stitched. When

I create a pattern for a holster I leave 3/8” to 1/2“

around the outline of the gun to accommodate the thickness

of both the gun and the leather.

Since I am right-handed, and carry my guns on my

right side, I always create right-handed patterns.

One of the reasons I like using a draw program is

because I can get nice smooth curves.

My curves weren’t very smooth when I drew the

patterns by hand; even using graph paper.

There are

a few things I always watch out for when designing this type

of holster; trust me - this is the voice of experience

talking:

- I

left enough of a gap between the front of the pistol

grip and the top edge of the holster so I could get my

fingers around the grip.

I’ve made holsters before that looked good on

paper, but I couldn’t grip the gun because the holster

got in the way.

- I

also made sure there was no leather covering the point

where the trigger guard met the front of the grip.

Again, leather here could interfere with my

ability to grip and draw the gun.

- My

belt should cross the gun at the halfway point, or

higher; preferably at the center of gravity (where the

loaded gun balances on your finger).

Any lower and the gun will have a tendency to tip

outward, away from my body.

I like to have the gun fit snuggly against my

body.

Once the

pattern was completed, I printed it out on regular printer

paper. Then I

cut out the pattern using regular scissors.

I used a ruler and a knife to cut the straight edges.

Since this pattern will be used for both the left and

right halves of the holster, I like to mark the front and

back of the pattern for left and right sides.

Since my pattern was a right-handed pattern, I put

the letter R on the side of the pattern with the

lines/printing. I

put a letter L on the back or clean side of the pattern.

Step

3: Trace the

Pattern onto Leather and Cut Out the Pieces

Leather is sold by ounces; but this refers to the thickness,

not the actual weight. One

ounce is equivalent to 1/64 of an inch.

I like to use 8-9 ounce leather for my holsters which

is 8/64” – 9/64” thick.

Most commercial holster makers use 5-6 oz. leather

because it leaves a nice mold of the gun when wet molded.

Unfortunately, holsters made of thinner leather have

a tendency to collapse; especially if worn inside the pants.

I prefer thicker leather, up to 10 oz., because it

holds its shape and won’t collapse.

I took a

sponge and moistened the smooth side of the leather, then I

laid the pattern on the leather and traced around it with a

stylus or pencil. I

also traced the vertical stitching lines, not

the outside or edge stitching lines.

These will be cut with a grooving tool later.

I never use a pen because the oils from the ink can

smear and ruin the holster.

Then I flipped the pattern over and again used a

pencil to trace the pattern onto a different section of

leather.

After

tracing the pattern onto the leather, I used a sharp,

break-away knife to cut out the pieces.

I like to use the dime-store knives with break-away

blades that retract into a plastic handle.

Leather will dull a knife blade very quickly; the

breakaway blades are cheap, and by breaking off the dull

segment, a new, sharp segment is exposed.

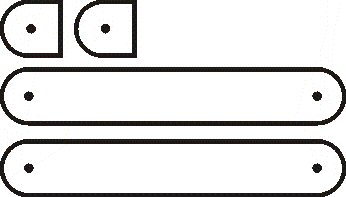

Since I

planned to wear this holster inside the pants, I needed 4

additional pieces; 2 straps 4 3/4” x 3/4“ and two

spacers, 1/2“ x 3/4“.

I cut these from 7 oz. leather.

The straps are the belt loops and the spacers leave

space for my pants material between the belt loops and the

holster.

Step

4: Prepare and

Finish the Leather

Next I

cut a stitching groove around the edge of the leather.

The leather should be dry for this step.

This groove allows the stitching to sit flush or

below the surface of the leather so it won’t wear.

The tool shown above is set to cut the groove 1/8”

in from the edge. I

then took a straight grooving tool and cut the stitching

grooves in the middle of the leather.

I then

removed the sharp edges of the leather with a beveling tool.

I beveled all around the outside (smooth) edge of

both pieces. I

beveled the inside (rough) edges only where the two pieces

would not be touching.

After beveling I took a wet sponge and moistened the

edges only where the gun would sit, not where the

pieces of leather would be touching, and used a slicker tool

to slick and round those edges.

I also beveled and slicked completely around both

sides of each belt loop, but I did not bevel the edges of

the spacers.

Now

it’s time to finish the leather.

I prefer an oil-based dye such as Fiebing’s Pro-Oil

Dye available from Tandy

Leather Factory. I

applied the dye first to the edges, then evenly over

the front and back surfaces until the dye sat liquid on the

surface and the leather absorbed the dye very slowly.

I finished both holster pieces, the straps and

spacers and set them up on edge to dry.

I usually let them dry over night.

After the

pieces were completely dry I applied the leather finish.

I use Fiebing’s Leather Balm with Atom Wax; a

combination of wax and oil, also available from Tandy

Leather Factory. This

finish does darken the color of the leather so I have to

make sure I apply it evenly, it will leave unsightly

streaks. I

applied the finish to both sides, then after the finish

dried, I buffed the leather with a soft cloth.

This made a soft, lustrous finish.

I finished all the pieces in this manner.

Step

5: Assemble and

Stitch the Holster

Now

it’s time to assemble the holster.

Pancake holsters are simple to assemble.

I applied leather glue to the inside areas of the two

holster halves that would be touching, i.e. inside of the

stitch lines. Leather

glue is a type of contact cement so I had to wait for the

glue to dry. After

the glue dried, I pressed the two halves together making

sure the edges were even.

I have a

$1,500 leather sewing machine that I use to stitch my

projects. But

for years I stitched my projects by hand.

Hand stitching is easy; here’s a simple method:

- I

run a #5 overstitch wheel in the groove I want to

stitch. The

overstitch wheel has evenly spaced teeth that leave

marks where the stitches should go.

- I

use a high speed rotary tool running at a moderate speed

with a 1/16” bit and drill a hole everyplace the

overstitch wheel left a mark.

- I

use two needles and waxed thread to saddle-stitch the

seam.

Saddle

stitching is very strong and involves running two threaded

needles through each hole, one from the front and one from

the back. I

start at one hole and run half of the thread through that

hole. I use a

piece of scrap leather to push the needle through the hole,

then a pair of pliers to finish pulling the needle through.

For the next hole I run the front needle through from

the front, then the back needle through the same hole from

the back. I then

pull the loose ends tight.

When I reach the end of the stitching, I then stitch

back 3 holes, then cut off the leftover thread.

This locks the stitching so it will not come apart.

With the

holster still flat I cut the belt notches.

I used a 3/8“ round punch to punch each end of the

notch, then used my knife to cut between the outside edges

of the holes. Once

the center is removed I used my beveling tool to bevel the

sharp edges. I

also punched a small hole above each notch to accommodate

the screw to attach the belt loop.

Finally,

I used my high speed rotary tool with a fine sanding drum

set at a low RPM and went over every stitched seam to make

them smooth and even. This

sanding process makes a lot of leather dust so I always wear

goggles and a mask to prevent the dust from entering my eyes

or lungs. After

sanding the seams I again beveled the edges with the

beveling tool to ensure there were no sharp edges.

Step

6: Wet Mold the

Holster to the Gun

First I

placed the gun into a plastic bag.

Usually, a gallon freezer bag works well.

Then I half filled a sink with water and immersed the

holster. With

the holster completely immersed I worked it with my hands

until it became soft and pliable.

This only took about 30 seconds.

I removed

the holster from the water and inserted the plastic-wrapped

gun as far as it would go.

I took my fingers and molded the leather to the shape

of the gun. Once

I got the leather molded I left the gun in the holster until

the outside was dry, then removed the gun to allow the

inside to dry. It

was interesting to note that while the holster was wet it

would activate the laser.

Once the holster was dry, however, I could insert and

remove the gun without activating the laser.

This

wet-molding process not only molds the holster to the shape

of the gun, but it also causes the leather to become stiff

which helps to prevent it from collapsing when I wear it

inside my pants.

After the

holster was dry I applied another coat of leather finish,

then applied a dark brown edge dressing to the edges,

including the inside of the belt notches.

This provides protection to the edges and gives the

holster a professional look.

Step

7: Attach

Hardware

Although

not shown in the photos, I also finished the straps and

spacers in the same manner.

After they were dry and buffed I attached large

chrome snaps to the straps.

I ran a #6 screw through the bottom of the snap set,

through one end of the strap, through the spacer, then

through the small hole I punched in above the belt notch in

the holster. The

holes in the snaps are just large enough to accept a #6

screw. I used a

#6 nut to attach the screw to the back of the leather.

The

holster is now complete, and because of the wet molding

process, the gun fits perfectly.

The belt notches allow me to wear the holster on my

belt outside of the pants, and the belt loops allow me to

wear it inside the pants for deep concealability.

Finding a commercially-made holster that will

accommodate a laser is virtually impossible, but I can

always make one that will always be a perfect fit and will

meet my needs perfectly.