1911

Action Job

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Introduction

I recently purchased a Rock Island Armory 1911A1-45 FS GI made

by Armscor

of the

Philippines

. This is a WWI

military pattern 1911 clone in .45 ACP with a parkerized

finish. It has a

few modern improvements such as a throated chamber, polished

feed ramp, and roll-over notch.

It got great reviews on the Internet and the price was

right.

The trigger

let-off was heavy at 6 1/2 pounds and was long with a lot of

creep. This was

caused by rough cut hammer and sear engagement surfaces and

long hammer hooks. The

hammer hooks measured 35-thousandths of an inch; much too long

for a crisp trigger. So,

I needed to reduce the length of the hammer hooks and polish

and hammer and sear engagement surfaces.

CAUTION:

Working on hammer and sear engagement surfaces requires

special tools and cannot/ should not be performed without

them! Without the

use of these special tools the surfaces can become rounded and

uneven and could cause the firearm to become unsafe.

Tools

Many years

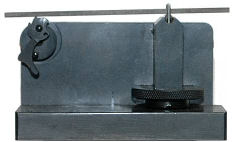

ago I purchased a Bob Marvel 1911 Auto Sear & Hammer Jig

from Brownells.

This jig allows me to work on both the hammer and sear;

other jigs on the market would only allow me to work on one or

the other.

I also

purchased the recommended medium-fine and extra-fine ceramic

stones from Brownells.

These stones are perfectly flat and square and are the

right tool for this type of work.

The sharp edges fit into the corner of the hammer hooks

so the entire surface gets polished.

To reduce

the length of the hammer hooks I used a Power Custom Series I

Stoning Fixture that I also purchased from Brownells

along with the 45 adapter.

These can also be purchased from MidwayUSA.

For cutting I used a 220-grit silicon-carbide polishing

stick I purchased from Boride

Engineered Abrasives.

Their Gunsmith

Action Kit contains a number of different stones and grits

I regularly use for gunsmithing work.

Reducing

Hammer Hook Length

The instructions that came with the Marvel jig stated that the

hammer hooks should be reduced to 0.018” – 0.020”.

I decided to reduce the length to 0.025” and work

from there.

I removed

the hammer strut pin and hammer strut from the hammer.

I installed the 45 adapter onto the Power Custom Series

I Stoning Fixture then installed the hammer onto the adapter

with the hooks pointing up.

I used the 220-grit silicon-carbide stick coated with

gun oil and polished the hooks until they measured 0.025”.

The jig ensured that the ends of the hooks were even

and square. I went

very slowly here and measured often.

Because of the coarse stone it only took about 10-15

passes to get the proper length.

I installed

the hammer onto the Marvel jig following the instructions.

I used the black ceramic stick to perform the initial

polishing, then finished with the white ceramic stick.

Ceramic sticks use water as the cutting/cleaning agent;

I never use oil on a ceramic stick.

Next I

disassembled the frame and again following the Marvel jig

instructions, installed the sear onto the jig.

When adjusting the height if the sear above the top of

the jig I use a 0.0015” shim under the front of the

polishing stick and raise the height adjustment until the sear

is just touching the bottom of the stick.

If the sear is too high the angle of the sear would be

changed.

I used the

black ceramic stick to polish the sear so it was straight

across. Many sears

I have polished were cut crooked, but the jig ensures it is

cut straight. After

using the black stick, I used the white ceramic stick to final

polish the surface.

Finally I

cut the break-away angle on the rear of the sear so that about

0.020” of engagement surface was left.

This provides a nice, crisp trigger pull.

I used a

toothpick to apply a very small amount of Brownell’s

Action Lube Plus® to the corner of the hammer hooks

before reassembling the gun.

After the gun was assembled I cocked the hammer,

applied pressure to the rear of the hammer with the thumb of

my left hand, and pulled the trigger.

This is called “pushing the hammer” which helps the

hammer and sear seat together quicker.

Finally I allowed the slide to slam home with no

magazine in place to test if I had any hammer follow.

This is a very unsafe condition which usually results

in having to replace the hammer, sear, or both.

I did not have any hammer follow.

By the way, this should not be performed very often as

it can damage the slide and frame.

The sear

now breaks crisply and cleanly at 4 1/2 pounds with no grit or

creep. The

investment for tooling for jigs and stones can be fairly

expensive, but the results make the investment well

worthwhile. If I

had reduced the length of the hooks to 0.020 I could have

reduced the pull weight even farther.

I have a couple of 1911’s that I build from all

hand-fitted parts and their sears release at 2 3/4 pounds.

|