Making a 1911 Front Sight Staking Tool

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Introduction

I recently purchased an Armscor Rock Island Armory M1911A1

to use for Wild Bunch match competition. I spent a lot of

time fine-tuning this gun to avoid having to shoot 500

rounds to break it in as suggested in the owner’s manual

(refer to my article

Fine-Tuning a Rock Island Armory M1911A1).

I

didn’t like the narrow WWI front sight that came with the

gun so I fabricated and installed a taller rear sight, and a

taller wider front sight. I have fabricated and installed

dovetail sights on 1911’s in the past (refer to my article

Milling a Front Sight Dovetail), but I wanted to

maintain the original factory installation by staking the

front sight in place. I found some sources on the Internet

that said to use a prick punch and 1/8” steel punch to peen

the end of the sight, but this came out ragged and looked

really ugly, and eventually the front sight became loose.

One reason the sight became loose was because the tenon was

too short so there wasn’t enough metal to peen and hold the

sight in place. My next version had a longer tenon, but

using the punch method still looked ragged and

unprofessional.

The

factory front sight staking was smooth and concave; very

professional looking. I’m guessing Armscor used a tool

similar to the one described below.

Front

Sight Staking Tool

Brownells sells a front sight staking tool

#080-817-000 but I thought I could fabricate my own a

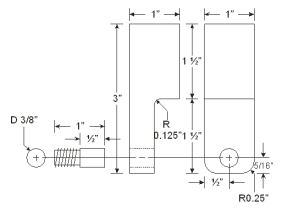

lot cheaper. I found a drawing on the Internet for a 1911

front sight staking tool which I have reproduced below.

The

body of the tool is supposed to be made of steel and a 3/8”

bolt is used for the anvil. Since I had a lot of scrap

aluminum that I purchased off of ebay many years ago I

decided to make the body out of aluminum. Aluminum probably

won’t last as long as steel, but it should be plenty strong

enough for the few times I need to use it. I also had some

four-inch 3/8 x 16 bolts so cost to me should be $0.00.

I

milled a piece of aluminum 1” x 1” x 3”, then milled 1/2”

off of the bottom half. I drilled a 5/16” hole 5/16” up

from the bottom and threaded it with a 3/8 x 16 tap.

To

fabricate the anvil I used a hack saw to cut off the

threaded part of a 3/8 bolt leaving 1/2” of threads. I then

cut the unthreaded shank leaving 1/2”. I applied some red

Loctite 271 to the threads and installed the anvil into the

3/8” tapped hole.

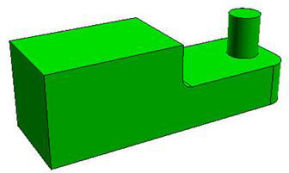

Ok, so

how does it work? The above photo shows the tool in place.

Notice the small piece of brass under the bottom of the

tool. The new front sight is laying on this piece of brass

to prevent the top of the sight from becoming deformed

during the staking process. The blue painter’s tape

prevents the sides of the slide from becoming scratched or

marred.

A few

gentle taps with a mallet and the tenon was perfectly peened.

This didn’t seem to affect the aluminum body at all. Notice

in the above photo how the peened end completely fills the

recess cut in the slide and is smooth and round. I couldn’t

do that with punches. Because the sight is now perfectly

staked in place it should last for thousands of rounds and

not shoot loose.

|